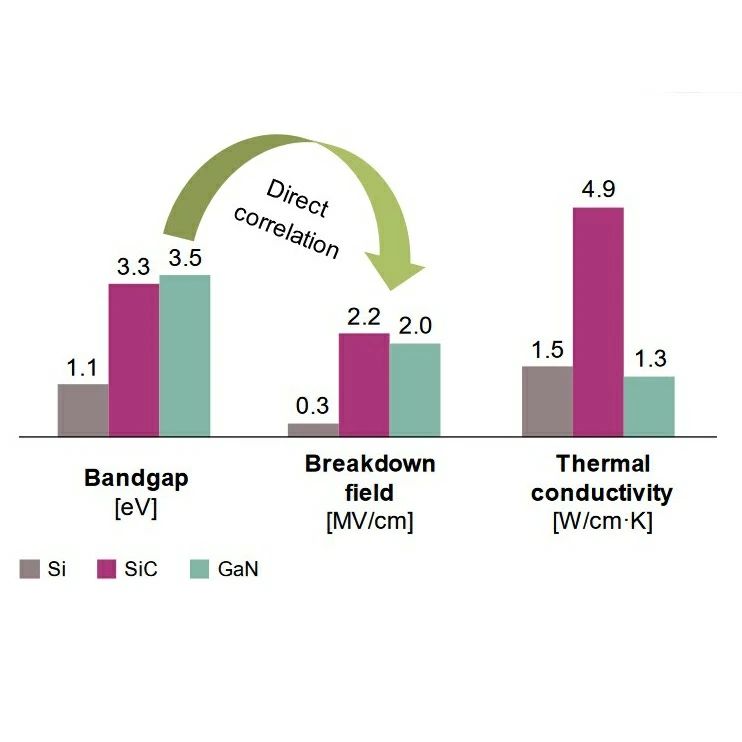

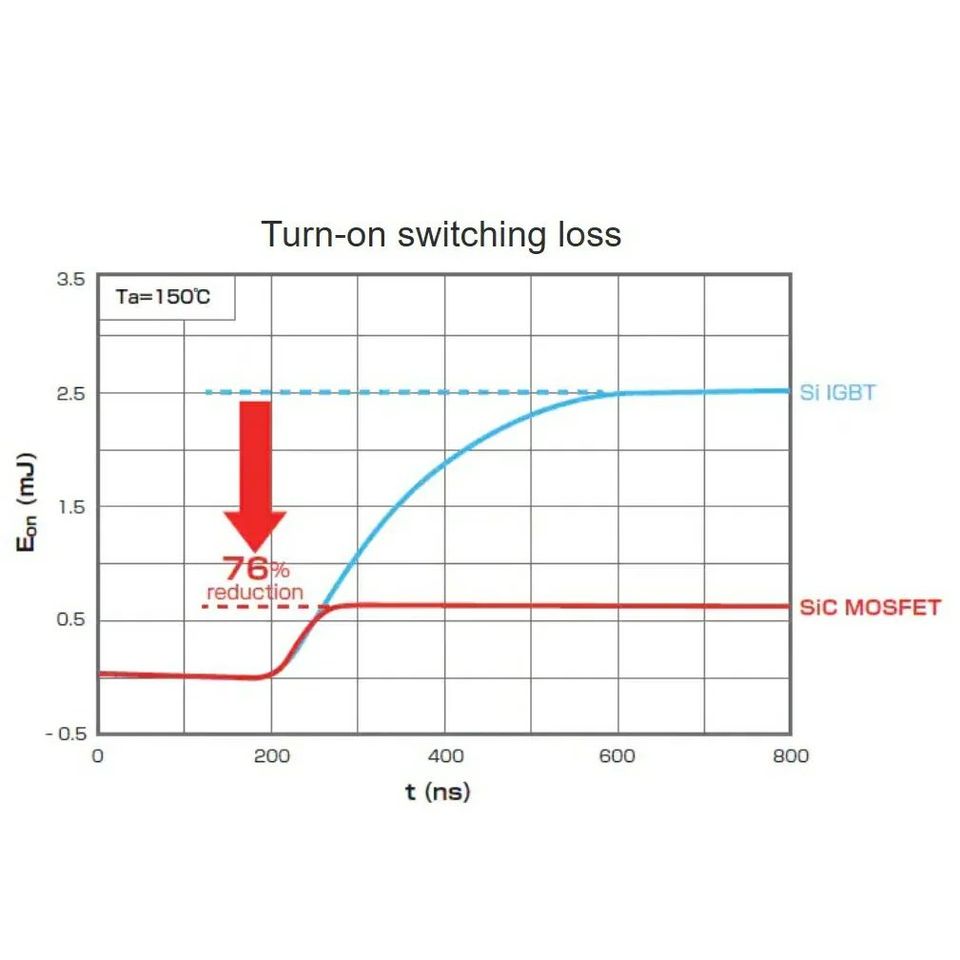

Have been reading about these for a while. Seems that this is one of the best things that has happened in power electronics in a long time. Mostly used in Power MOSFETs and Diodes, it uses Silicon Carbide(SiC) as the base material instead of the usual Silicon Wafers. SiC have advantages over Si with a wider energy bandgap and high critical breakdown field. Specifically for SiC MOSFETs, there are added advantages in having higher blocking voltage(The max voltage that can be applied to MOSFET), High thermal conductivity(Implies smaller heatsinks in system design) and reduction in switching losses, especially in higher switching frequencies.

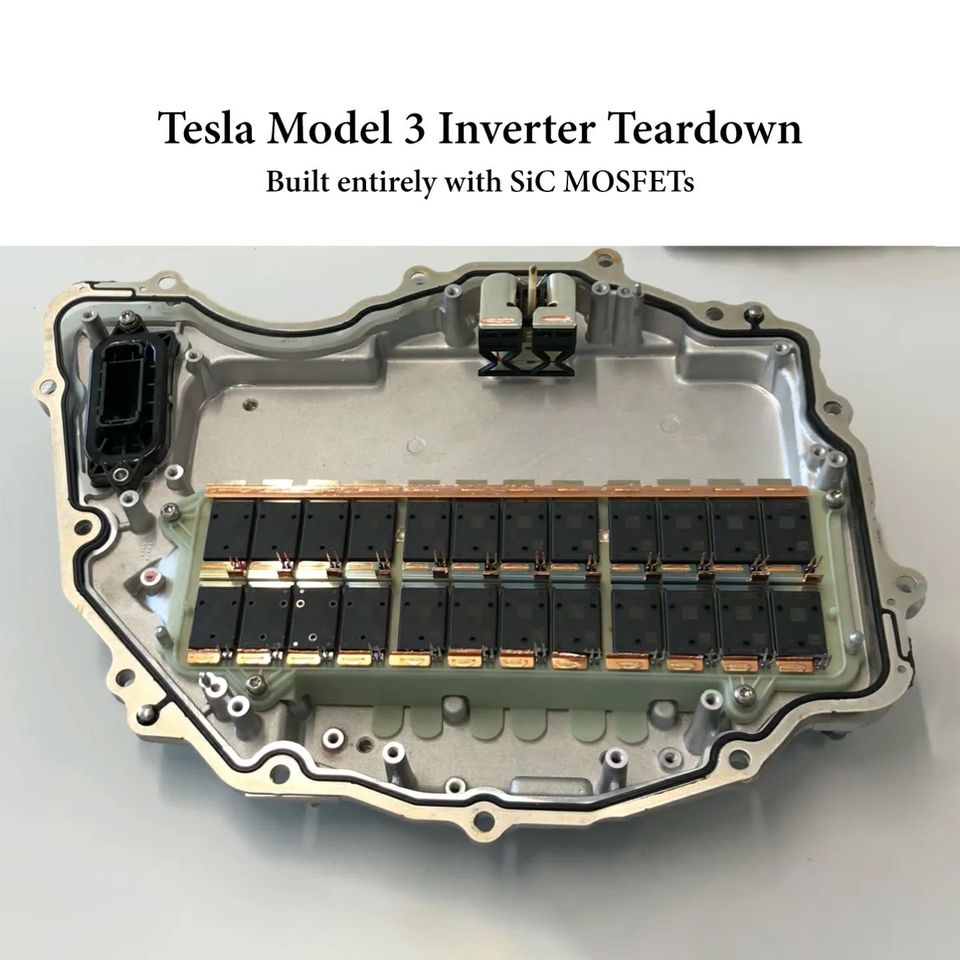

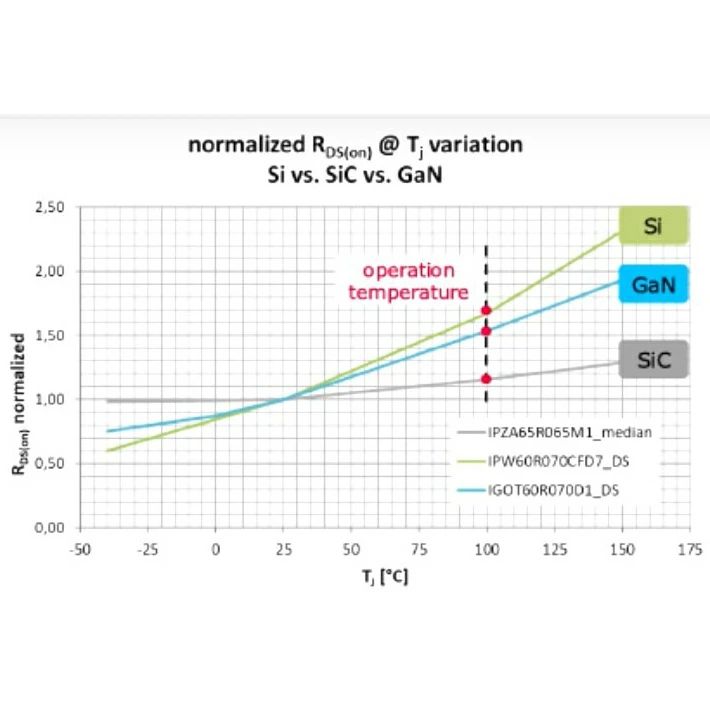

Mostly IGBTs are commonly used for high voltage and current applications. SiC MOSFETs are aiming to replace them. Although they are more expensive than IGBTs, the benefits they bring about in the overall system design are significant. They have wider operating temperature and their Rds ON values are more stable at higher temperatures compared with others. That ensures lower losses in heat. Lower losses mean smaller heatsinks which in turn reduces the weight of the solution. This becomes massive when considering power electronics inverter solutions in Electric vehicles. Lower weight means a longer overall range. There is a case study out there which says Tesla switched entirely to SiC MOSFETs and which made their inverter system weigh almost half that of its competitors. That is massive in terms of savings in the range.

I am relatively new to this domain, but I do see some immense great things happening in high-power electronics because of SiC devices. Folks in power electronics please do correct me if I’m wrong. Except currently for costs(being relatively new tech) SiC has everything going for it.

PS: Pics are sourced from various industry white papers

0 Comments

Comments are closed.