When I work with clients I see that most of them don’t know of this tool except for in large companies. Webench Power Designer is a superb tool online virtual wizard by Texas Instruments (TI) which can be used in power supply design. Have been a regular user of it for some time now and can’t recommend this enough.

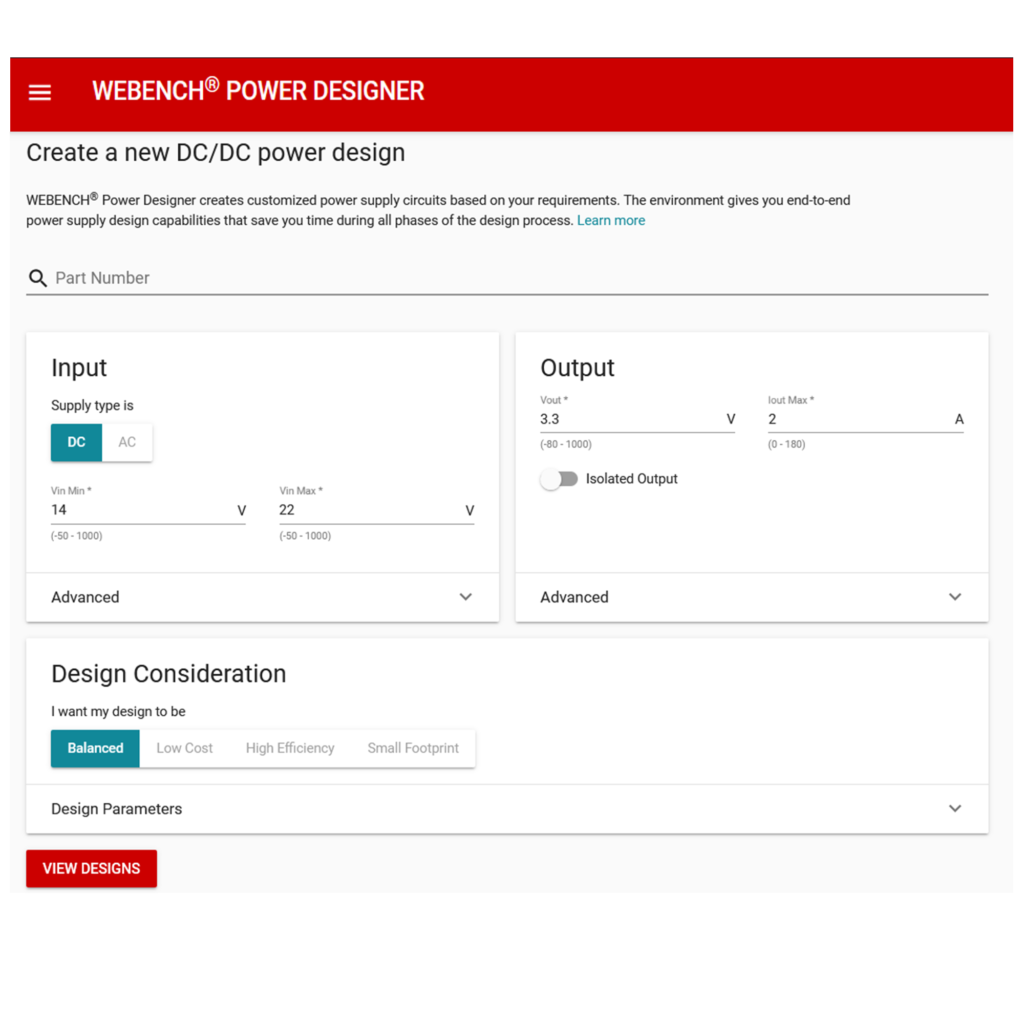

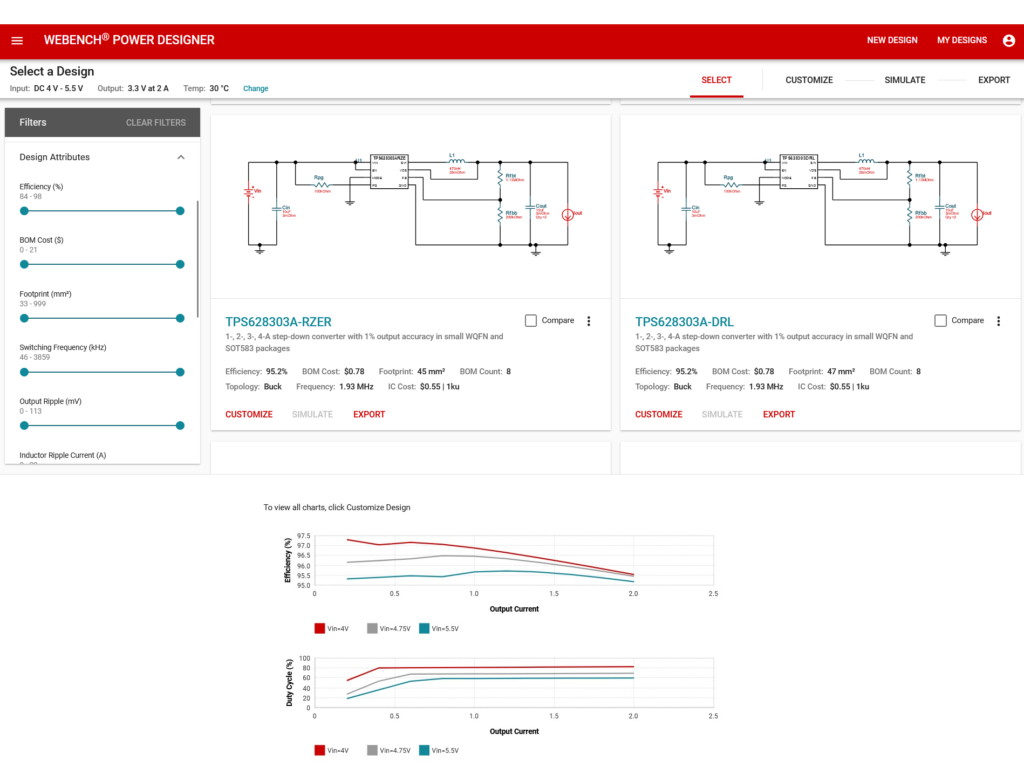

So what does it do? If you are building a power supply module, AC-DC or DC-DC, this tool allows you to feed in a few parameters like the input, output voltage range, current output, ripple, etc and gives you a massive list of usable designs using the ICs from TI. This design contains all the parts needed and the full BOM of passives. It even provides you with an optimal board layout which you can directly import into a few PCB CAD tools like Altium. It provides the necessary graphs and you can even export a simulation.

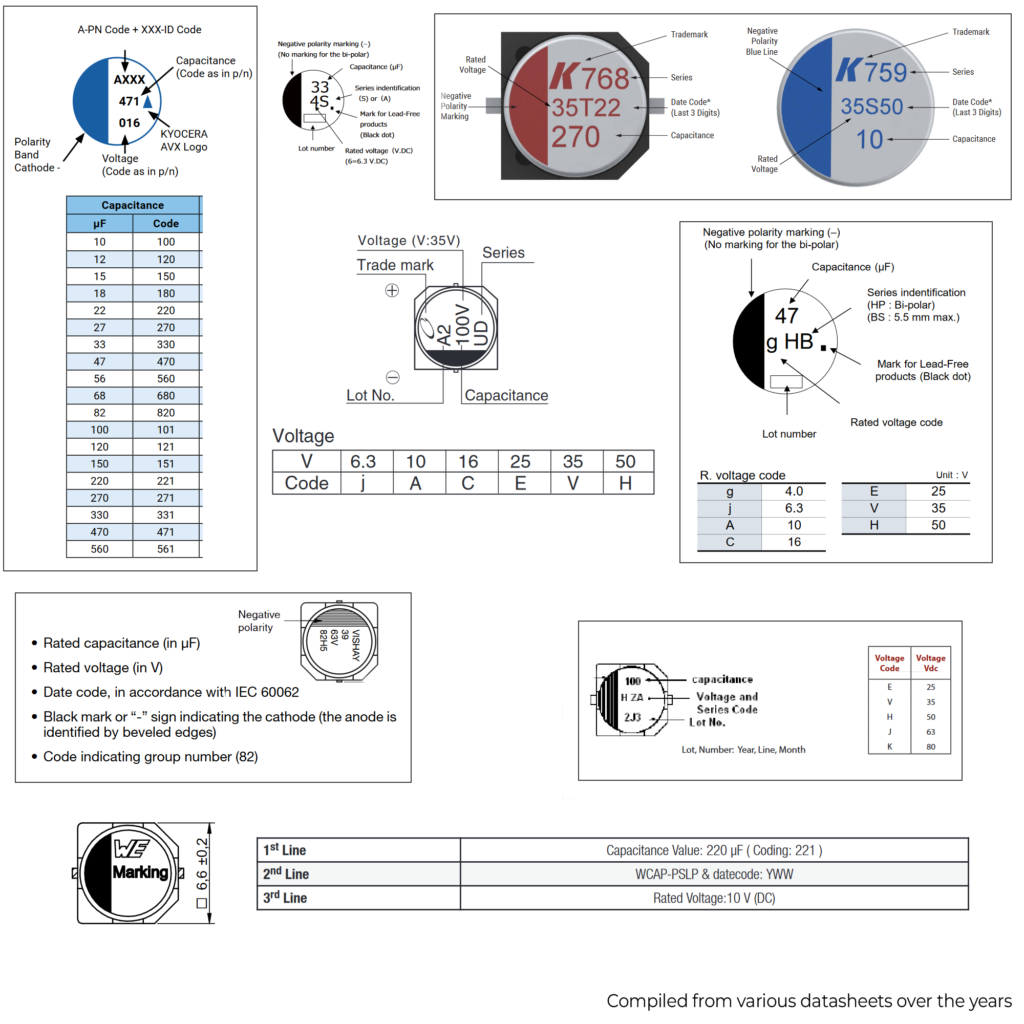

It has an awesome feature in which you can tell the tool to optimize for low BOM cost, High Efficiency, lowest PCB space footprint, or even a mix of all the above with a balanced view. This makes life simple for a newbie. It takes in all the datasheet design equations and spits out resistor, inductor, and capacitor values(But I double-check and redo it from the datasheet again, that’s just my paranoia, nothing else). The design it puts out is accurate and you can expect near simulation results if you implement that. I never had issues with it.

It gives you a list of TI’s massive power part ICs, you can pick a design and then fine-tune it if needed. If you have already selected a part, you can specify that in the tool to make a design around that part. I truly hope other companies can develop solutions similar to this using their product portfolio. If you are only working with TI parts for a design, it’s very well worth trying out. Real time saver.

For folks who have used it before, what was your experience with it?