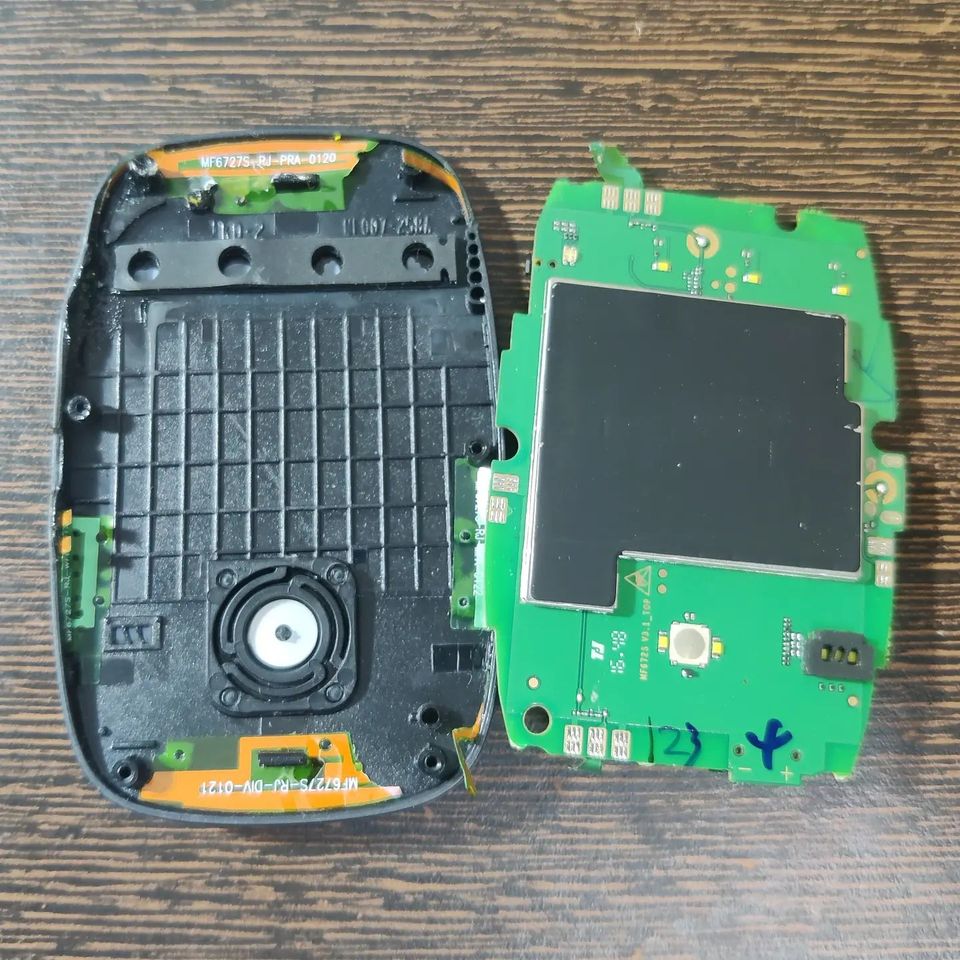

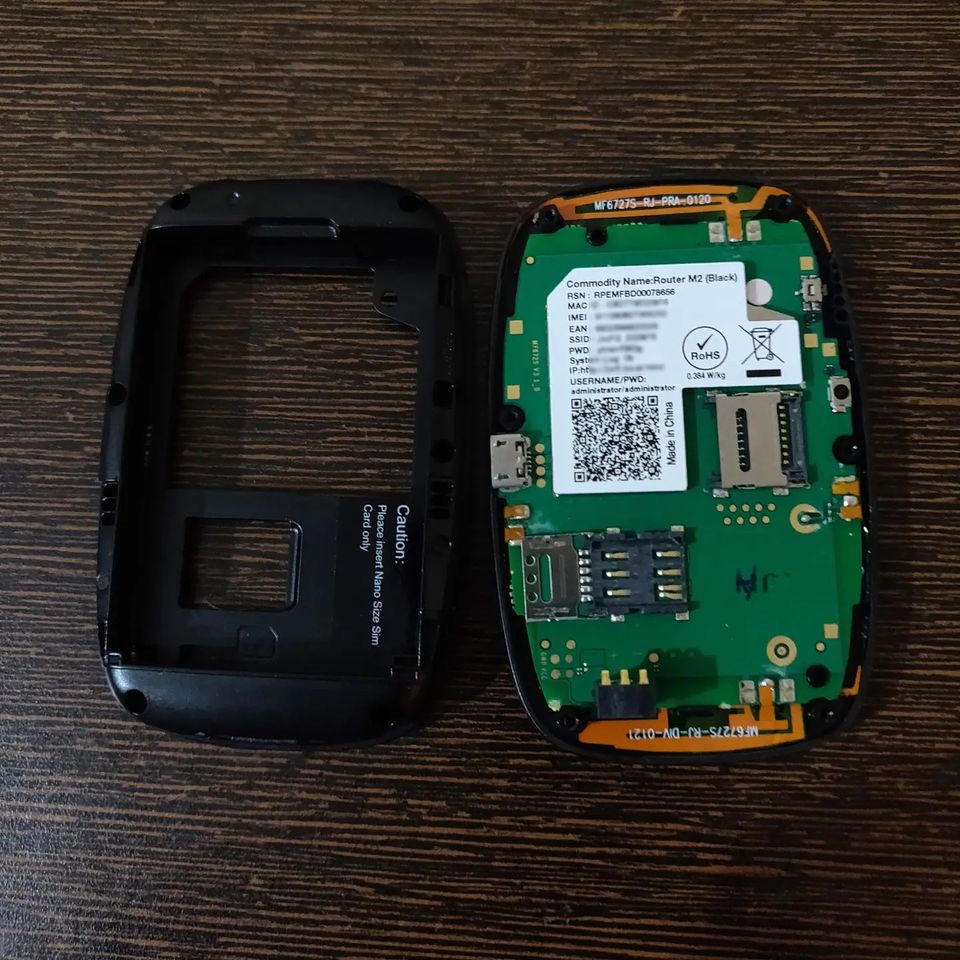

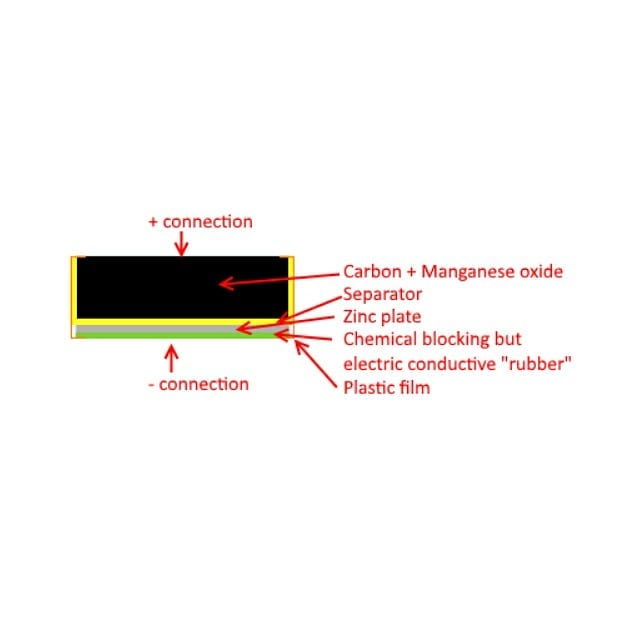

Somedays I just like to take apart stuff for the fun of learning how it’s engineered. Jio Hotspot device was something which was lying around unused for the last couple of years so I took it to bits. This teardown was destructive, to say the least. It wasn’t meant to be disassembled. It has an interesting construction with a 2300mAh (8.74Wh) Li-Ion battery. It has two massive RF shields on both sides of the PCB. Even removing one was a massive pain with lots of heat needed to remove it. The wireless networking is handled by RTL8192ES chip for WiFi-related RF communication. Power and battery charging is handled on the backside of the board. I was just not able to remove the back RF shield with heat, with the equipment I have. Need heating devices of large thermal capacity to remove it I suppose. I am assuming it will hold the main SoC(most likely from Mediatek). It consists of 4 flexible FR4 antennas on all sides for LTE and WiFi connectivity.

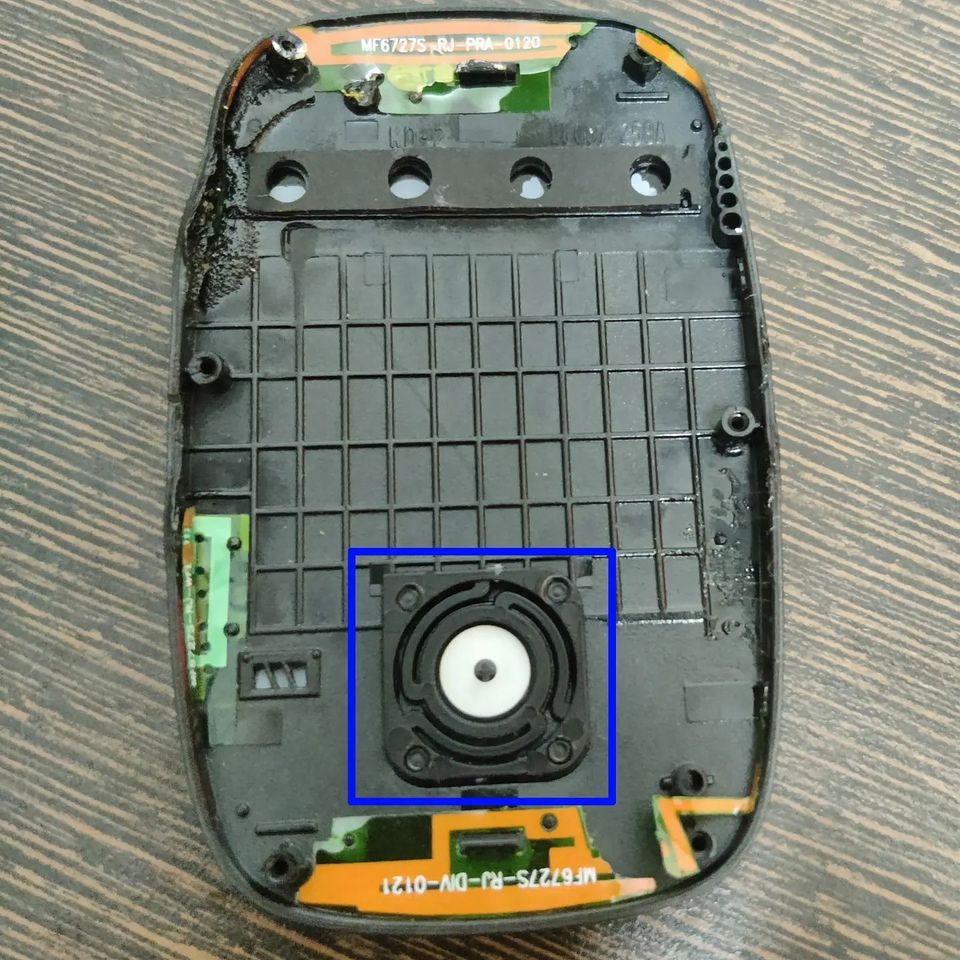

Doing teardowns will help you learn how a device is put together in terms of mechanical design too. Like, how is an external push button integrated with the case(Check out how beautifully the mechanical motion is achieved via a circular maze-like flexible button)? How is the lighting done with backlit symbols? There are a lot of things you can learn from things like these to help you become a better product engineer.

So My advice: Take stuff apart constantly. You won’t regret it.