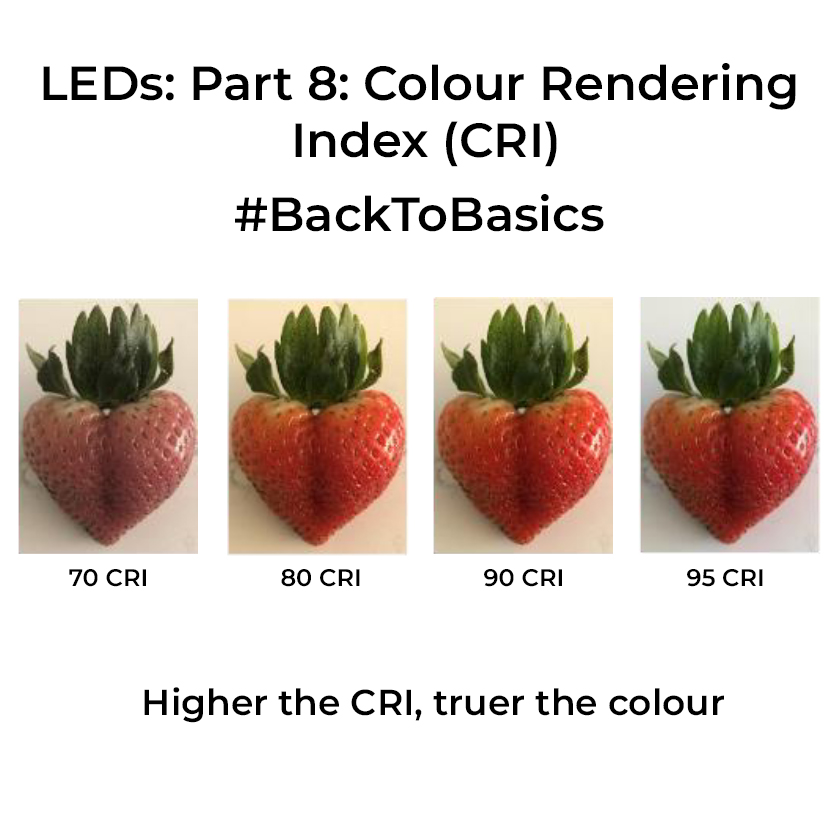

Today, let’s discuss a key aspect of LED lighting – the Colour Rendering Index or CRI. Imagine this: you’ve carefully selected your LED lights for let’s say a photography application, and yet, the colours in your space seem slightly off. This discrepancy might just be due to the CRI.

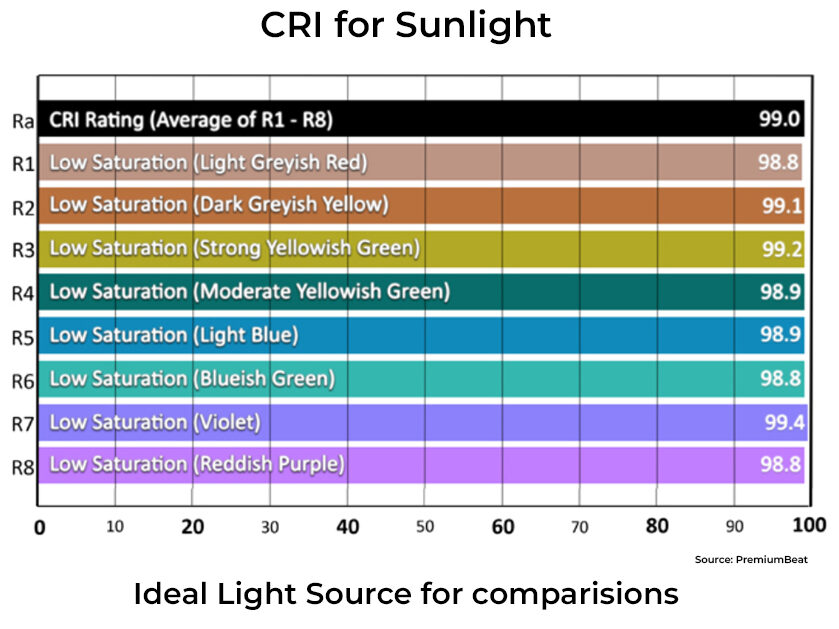

CRI essentially gauges how accurately a light source represents colours compared to natural daylight. Measured on a scale from 0 to 100, a higher CRI signifies truer colours. CRI is determined by assessing how a light source influences eight standard colour samples(called R1-R8), and comparing it to a reference source like tungsten or daylight. These samples represent a range of colours in the spectrum. Usually, a CRI of 90+ represents great colour reproduction. Check images for a comparison.

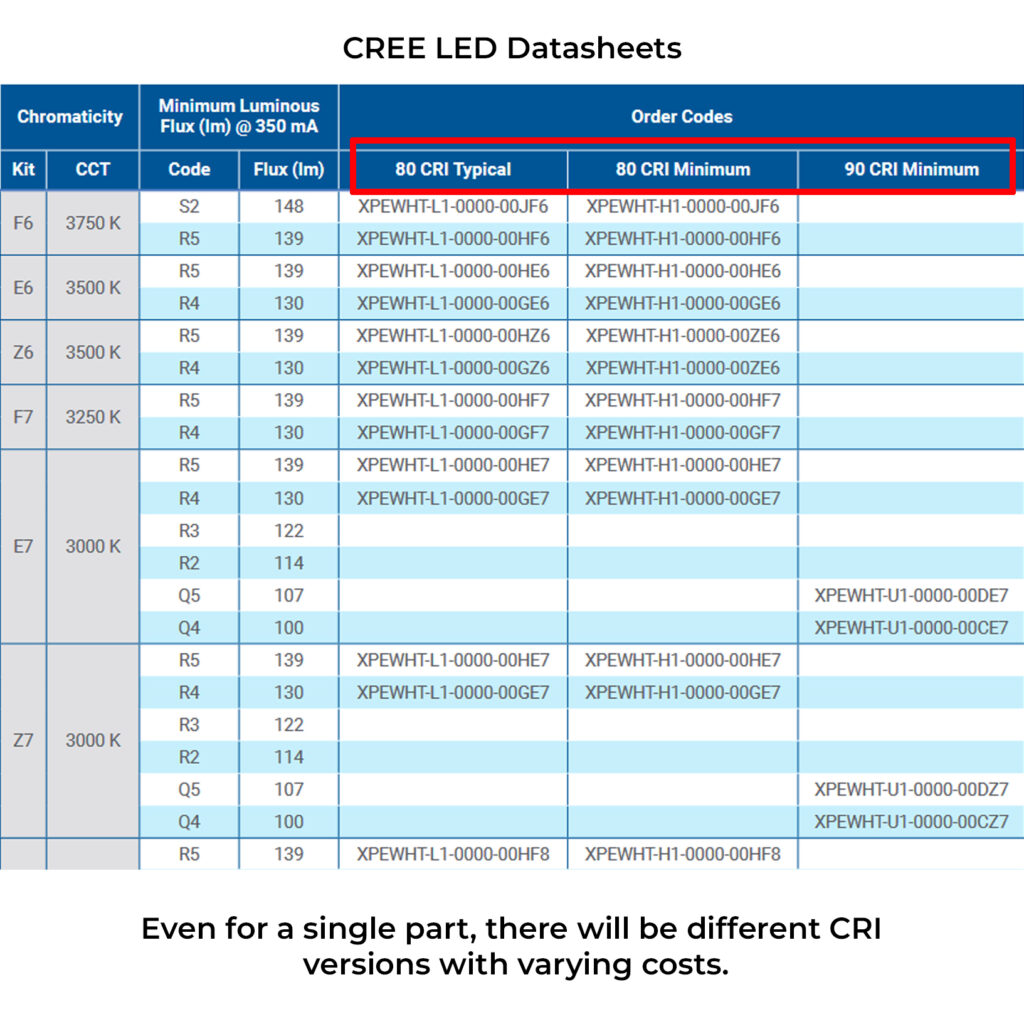

So What should you keep in mind while selecting LEDs for colour-sensitive application? Go through the datasheet thoroughly. Even for a particular part number of an LED, there will be various bins or subparts catering to different CRIs. Select part numbers based on that. A basic rule of thumb is to get something with a CRI value over 90 for these applications. Higher the CRI, higher the price. In certain specialized applications, additional colour scales like R9-R15, known as extended CRI, are used to further assess light quality. However, these details are usually absent in standard datasheets, except for highly customized LED solutions. CRI in LED selection is one of those decisions in life – you’ll know if you need it! ![]()