I only recently learned about the PicoLeaf tech from Murata. It’s a cool bit of tech worth discussing. Last time we discussed piezos and PicoLeaf takes this piezo tech to the next level.

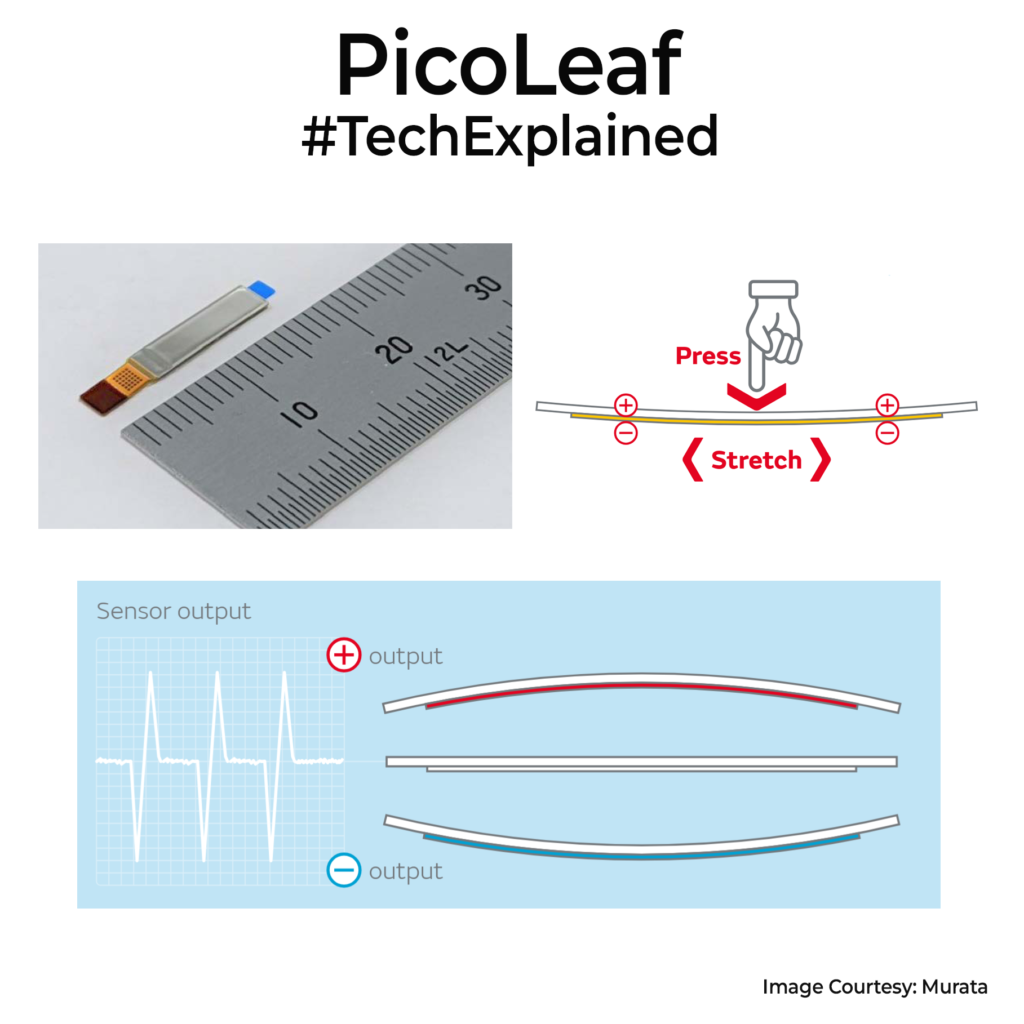

PicoLeaf is a flexible piezoelectric film sensor that can detect bend, twist, press and vibration. It’s thin(0.2mm) and tiny, so it wraps around curved parts. It’s even sensitive enough for µm-level motion, which is great for HMI and biosignal acquisition use without large parts. The film uses polylactic acid. Yes, PLA, the same stuff you use for FDM 3D printing. Murata orients the PLA to make it piezoelectric. It can be mounted on a device with a double-sided adhesives.

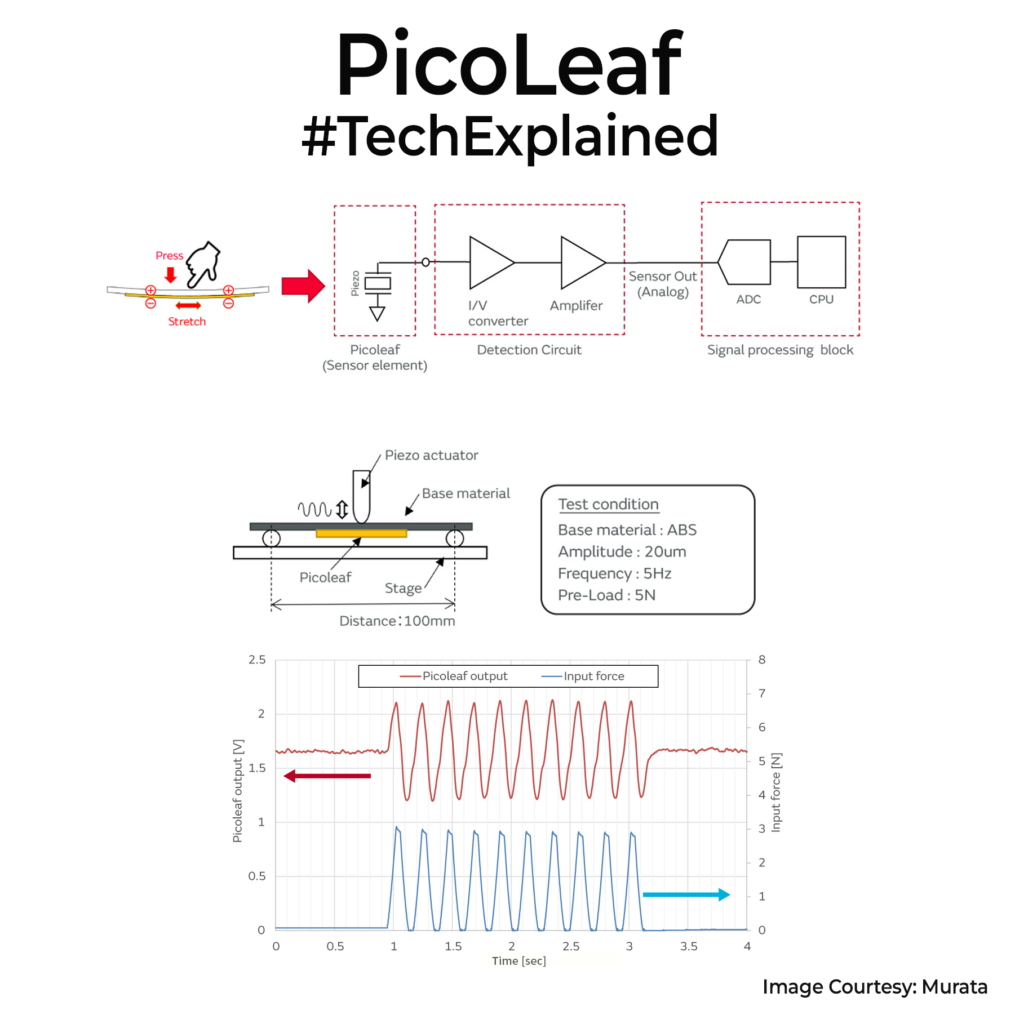

Like any piezo, it produces charge in proportion to strain rate. We can read it with a charge (I/V) amplifier (with a mid-supply bias) and then add gain and filtering to pass it to an ADC. All the taps/presses get captured nicely via the microcontrollers ADC at reasonable sampling rates. It can detect displacement direction(press/release) and displacement velocity based on signal amplitude. Its non-pyroelectric also, meaning no value drift because of heat. Power consumption is zero as its passive, so only power needed is for the driver portion in µA range.

The thin form factor opens up many applications. Since PLA transmits light, it can even sit under clear panels, making it useful for industrial touch displays that require a firm push. Sensitivity may be lower than capacitive touch, since the datasheet does not specify minimum activation force. It is well suited for flexible gloves to detect finger bends or sign gestures. If the claims are correct, it could be a breakthrough in robotic hands for grip sensing. With all the humanoids that planned in the next few years, PicoLeaf would fit right in. Murata’s tests shows it survives 500k bend cycles, which is great.

What I would love to see is whether it can also operate in reverse like a conventional piezo, producing mechanical motion when voltage is applied. With this form factor, that would be a killer feature.

0 Comments

Comments are closed.