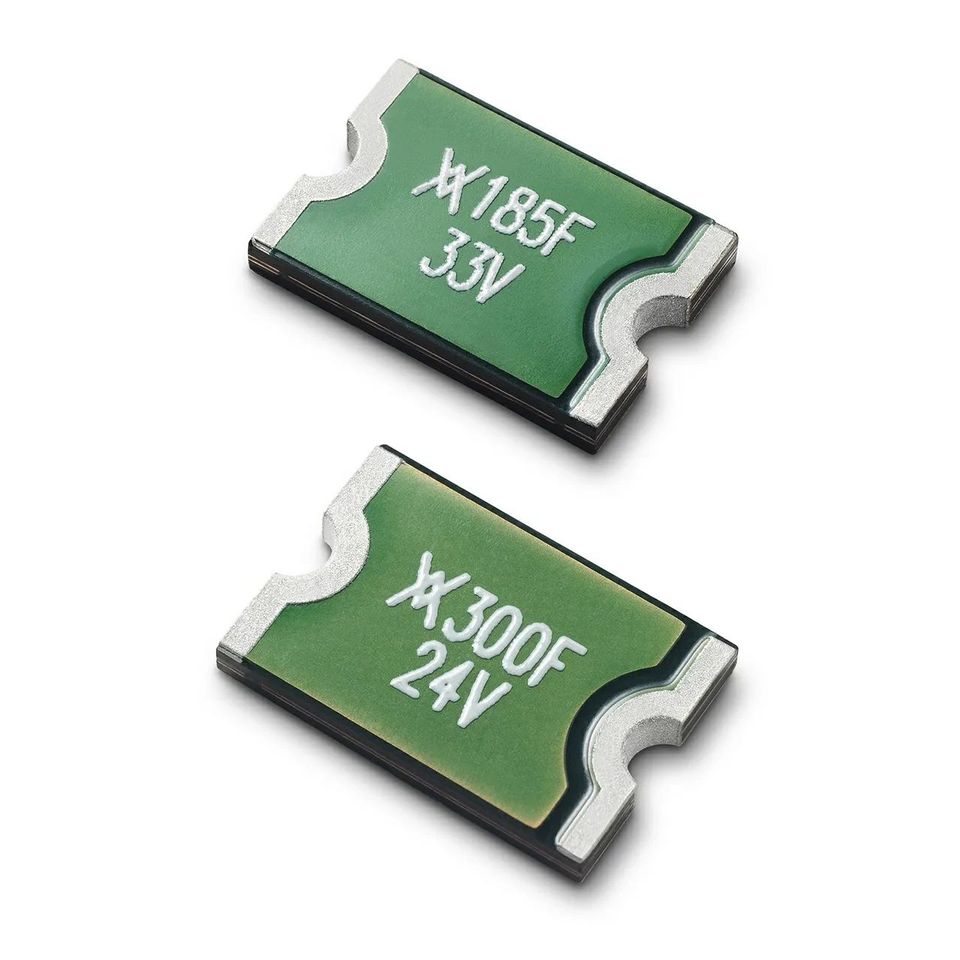

Resettable fuses are one of the commonly used components in an electrical design. If you have never used them, consider starting to use them if your device will be connecting to an external power source. In case of an accidental short, it’s a live saver for your circuits. These are components that will sacrifice themselves temporarily(Reusable) to protect circuits that follow them. There are a few things to consider when you are selecting fuses in your design and its important for any new designer to know what they are

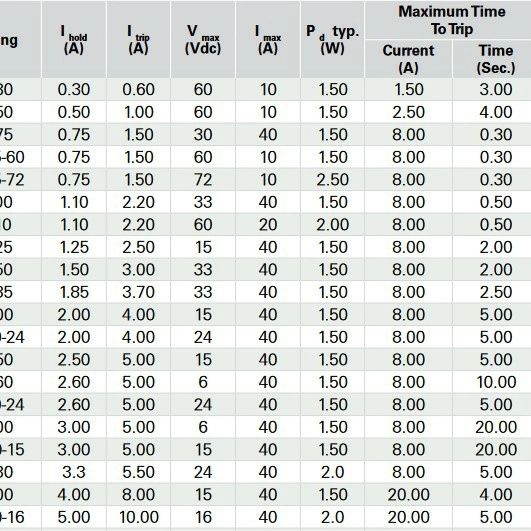

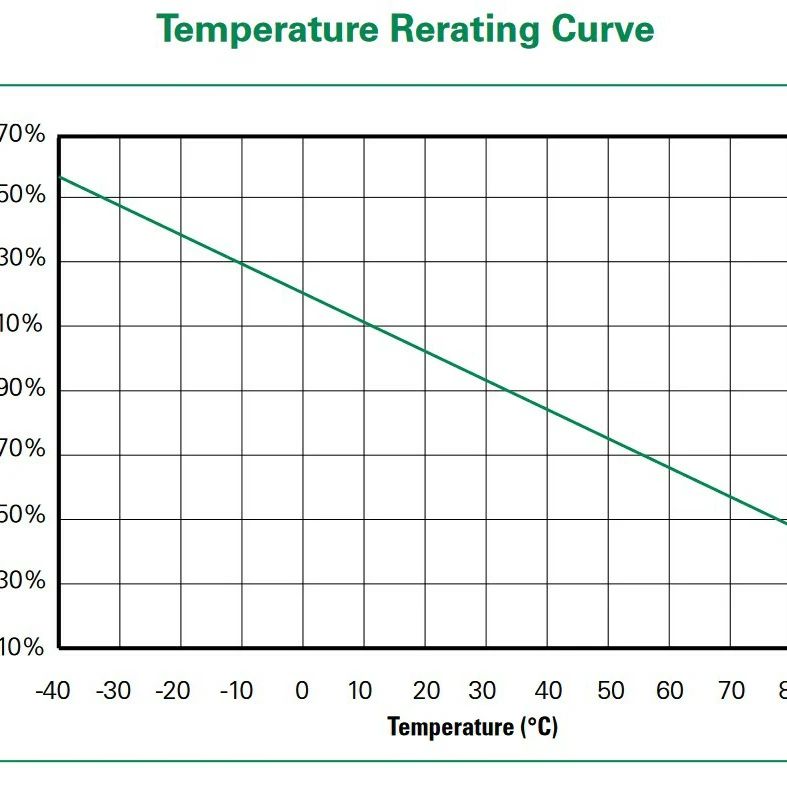

Trip Current: Minimum current needed to “trip” or stop the current flow at around 25C. This is the minimum current needed to activate your fuse, so make sure that your circuit current draw is less than this. This is the upper threshold and is dependent on temperature. Check the datasheet for graphs. Usually, this value will drop for larger ambient temperatures.

Hold Current: It’s the maximum current that the fuse can allow to go through it over a long time at around 25C. This number (or lower) should be what you should be designing your circuit input current for.

Trip Time: It’s the time taken by the fuse to activate when the trip current starts to flow. Lower the better.

Rated Voltage: Operating voltage of the fuse. Make sure your circuit voltages are below this number.

Always remember that PTC fuses are resistive based, meaning there will always be some I^2R power losses on the fuse during its normal use. There will be a voltage drop too as it’s connected in series. So try to select the fuses with lower resistance and always account for this voltage drop so that it doesn’t affect the circuit downstream. A classic example of this mistake might be that you are powering high power LEDs with constant voltage power input.