Kicking off an oscilloscope measurement and probe series with passive voltage probes. These are the most basic probes you see with any oscilloscope you buy. The only job of an oscilloscope probe is to transmit the measured signal(with all its freq components) reliably from the circuit to the front-end circuit of an oscilloscope without affecting the circuit it measures. How do you do that? Using your age-old voltage divider network with a high load impedance. This high impedance will cause the maximal signal to be dropped across the impedance so that you get the full signal. This is why you see most oscilloscopes with a 1MΩ input resistance.

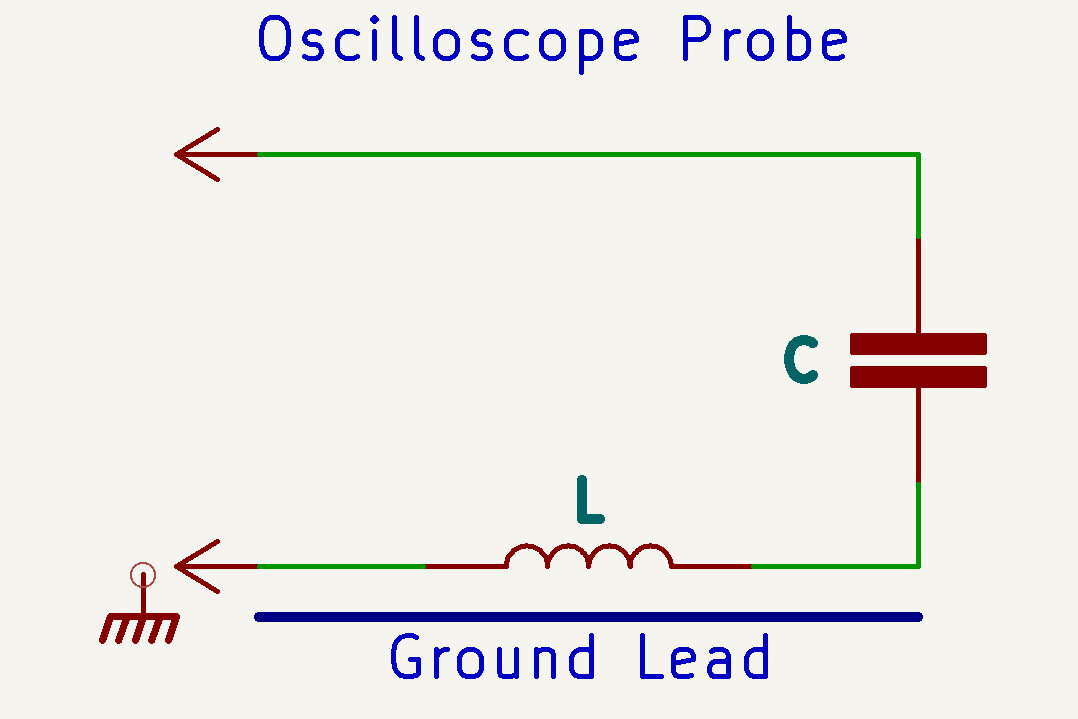

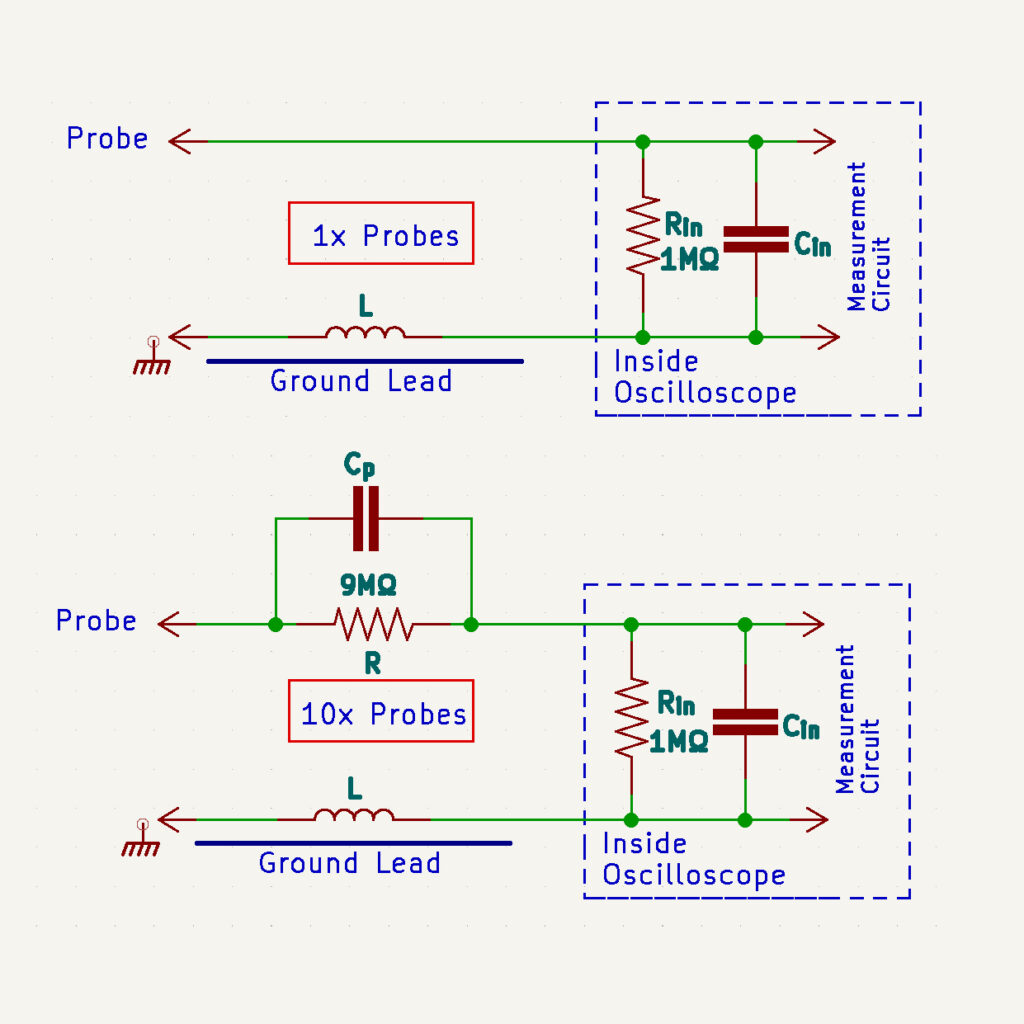

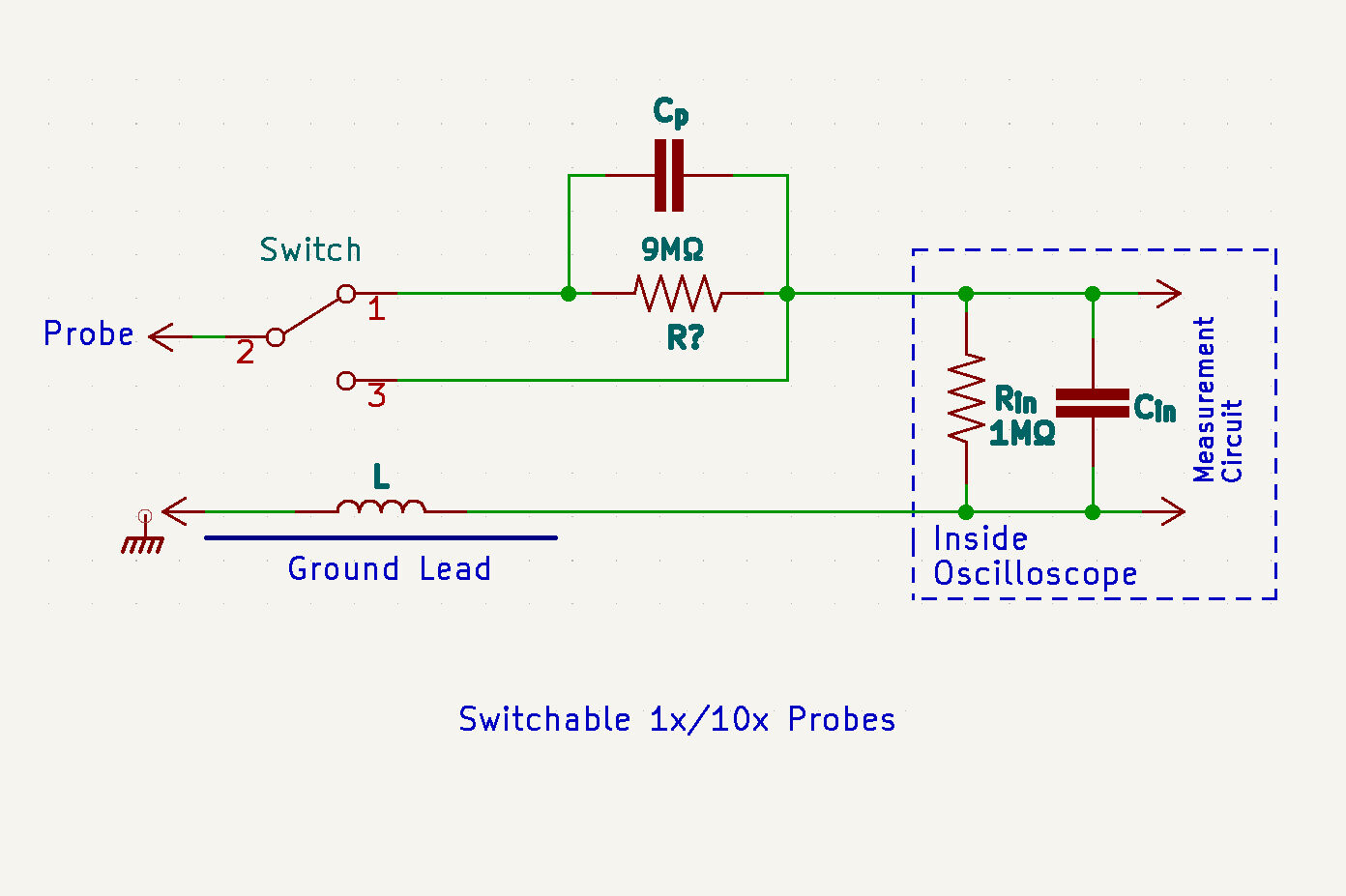

In order to measure a large range of amplitudes(so as to not damage the oscilloscope front-end measurement circuits), probes usually come with an attenuation factor built in called 1x,10x 100x, or Any x for that matter. It means that the signal is divided(NOT multiplied) by the factor mentioned. That means if a signal with 1Vpp in amplitude is measured with a 1x probe, the oscilloscope front end sees 1Vpp. Whereas with a 10x probe, this value will be 0.1Vpp. The images show the probe circuitry for 1x, 10x, and switchable 1x/10x probes. A 10x probe contains a 9MΩ resistor in series. It becomes a voltage divider and the Reff of the measurement circuit is = 1M/(9M+1M) = 1/10 or a 10x attenuation. You have a tunable capacitor Cp in parallel with the 9MΩ resistor for compensation(which we will get to later on in the series).

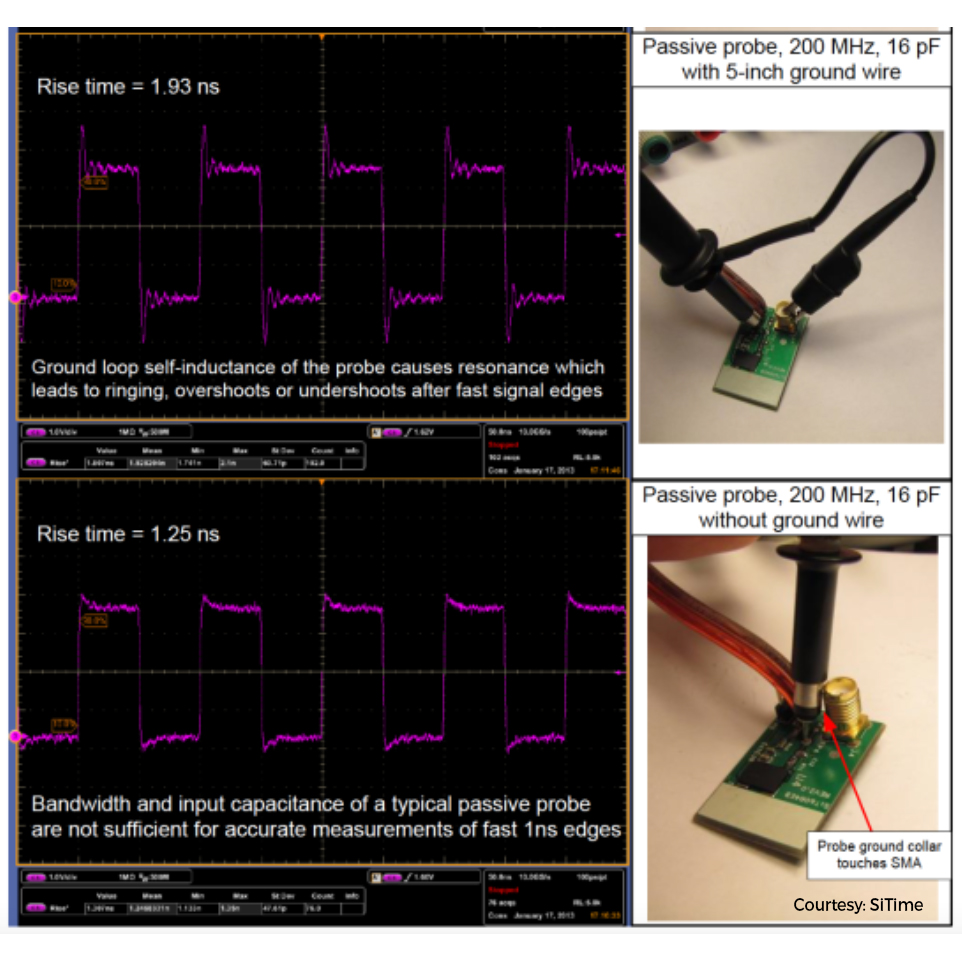

When to use them? 1x probes have high sensitivity and are great for low amplitude and low freq signals but have low bandwidth(We will discuss Why later on) whereas 10x probes have higher bandwidth, higher input impedance means the circuit being measured is not affected(Or not “Loaded” as you might say) and you can measure higher voltage amplitude range. When seeing the signals on screen always make sure that the correct setting on screen is selected based on if a 1x or 10x probe is used by you. I can’t even begin to count the number of times I goofed up that setting while measuring in my early days. ![]()