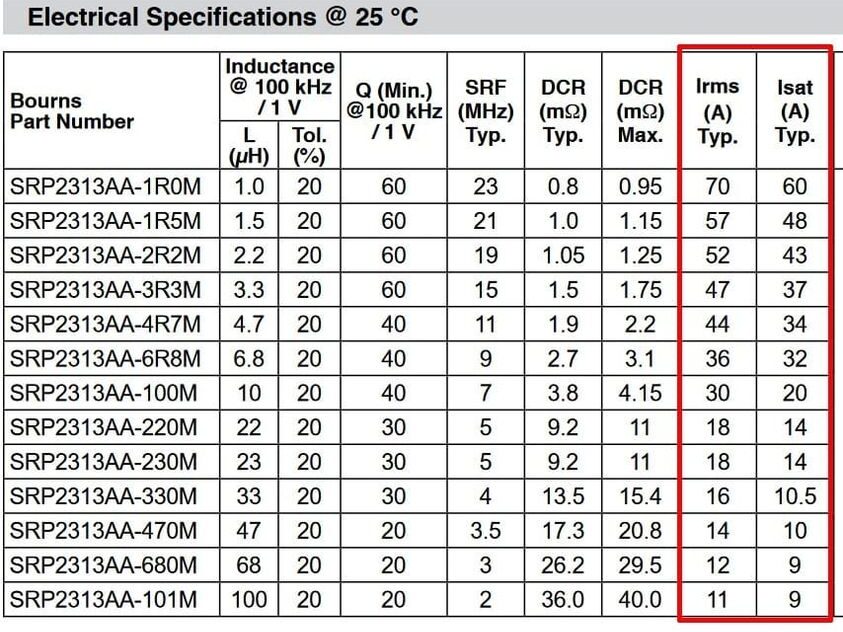

When choosing inductors in your design, one of the most confusing aspects is the rated current and saturation current values(there are other alias names like Irms, Itemp etc) mentioned in the datasheet. In older datasheets, these are rarely explained. What should you choose as the upper limit current rating for your inductors? Sometimes saturation currents are more than the rated current. It becomes a troublesome design choice till you understand what these actually are.

Rated current is the amount of current that can go through an inductor to heat it up by a fixed temperature value from the ambient(usually 40°C). Meaning if the rated current is 3.5A, once this amount of current is passed through the inductor and once a steady state is reached, the temperature of the inductor will be 65°C if the ambient temp is considered as 25°C.The saturation current mentioned in the datasheet is the current that when passed through the inductor, it becomes “saturated” and starts losing its inductance value by 20-30% of the original value.

So when choosing an inductor you can push the current values to maximum saturation current before inductor values start to drop(Ideally you shouldn’t but you can). You can pass more current than the rated value through an inductor, provided, you can give adequate cooling for your inductor. It’s given in a datasheet so that you don’t exceed the operating temp range of the inductor. If you are using the inductor in a use case where your ambient temp is 70°C, at rated current, the inductor temp will be 110°C which might be beyond the operating temp of the inductor packaging and it will stop working altogether.

So choose your inductors carefully. It’s not always about the inductance values alone.