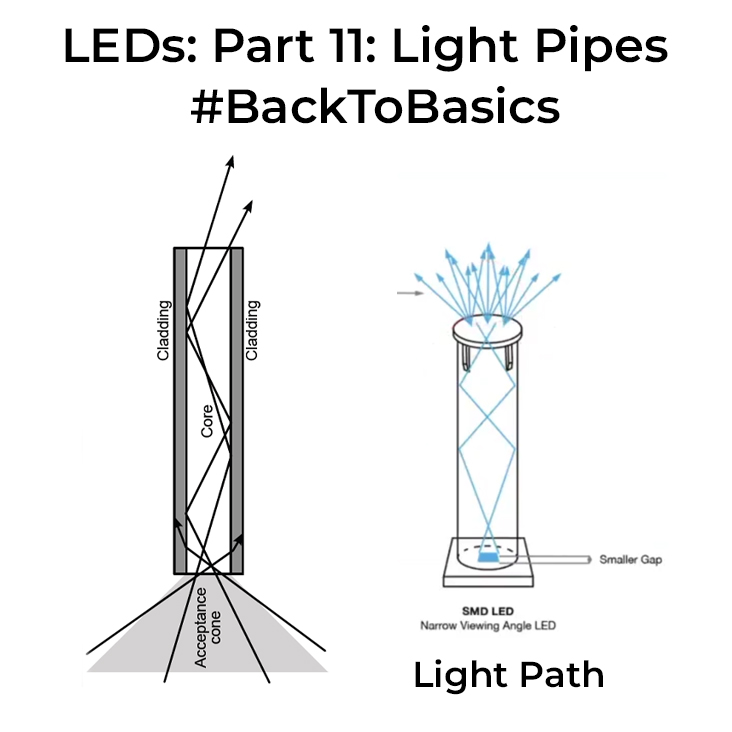

One of the harder problems I face when I design products with LEDs is how to get this light to the user on the product surface, esp. the indicator LEDs. How do you make them look good in a product? Enter Light Pipes. These are fundamentally mechanical parts made usually of transparent acrylic or polycarbonate to guide light from your LED source to the product surface. They operate based on Total Internal Reflection. Light enters at an angle greater than the critical angle, undergoes multiple internal reflections, and exits on the other side.

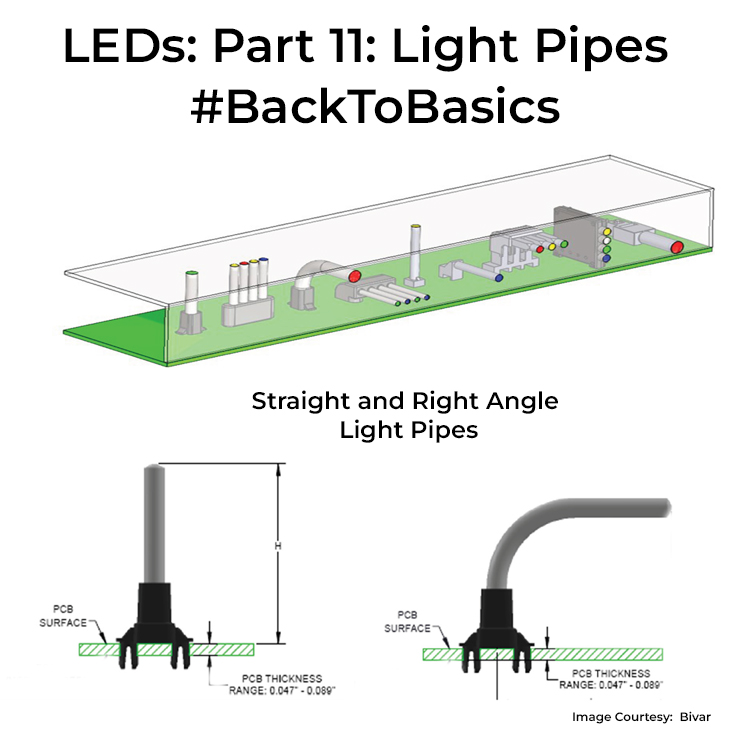

LightPipes come in two types, Rigid & flexible. Rigid ones are common in consumer products where the LED’s position is fixed, and the path to the surface is relatively straight. It can be mounted directly on a PCB in a straight line, or at a 90-degree angle in cases where a straight path isn’t feasible (Check images). For 90-degree LightPipes, a slight turn radius is advisable to minimize light losses. On the other hand, Flexible light pipes, typically crafted from optical fibers, can be bent into various shapes to achieve the desired light output.

The important consideration point is the light entering point between the LED and the pipe. Your goal is to ensure maximum light enters the pipe and minimize leakages. You can do that by having an opaque coupler or by reducing the distance between the LED and pipe to an absolute minimum(but not touching). Usually width of the input of the light pipe should be wider than the beam angle of the LEDs, so for these applications always prefer using LEDs with a lower beam angle for larger light coupling.

And there you have it! Wrapping up this LED series. It’s been fun. I’ve tried to cover all things LED-related, making it as enjoyable and informative for you as it was for me putting it together. Hoping you loved it. If I missed anything, give me a shout. See you next week with something else.

0 Comments

Comments are closed.