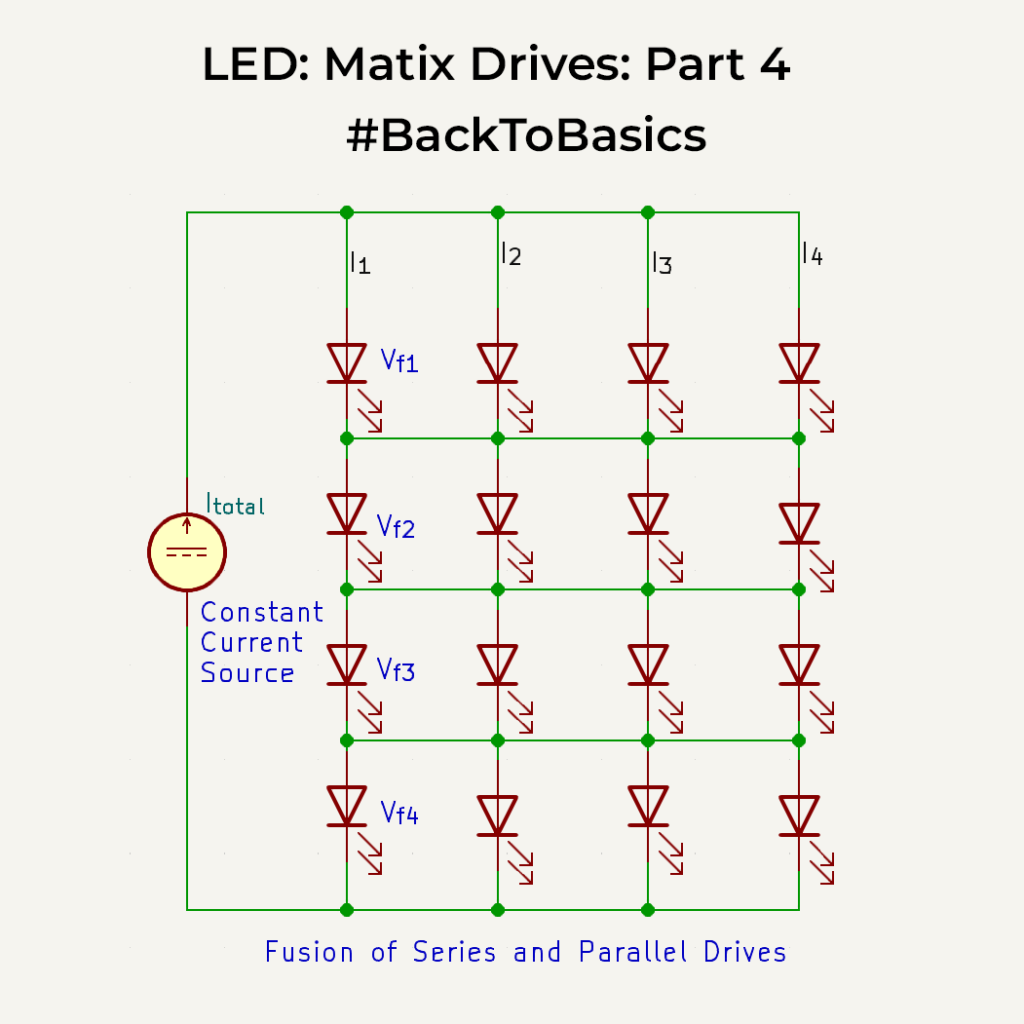

In our exploration of LED drives, we’ve looked into series and parallel setups. Now, let’s check the fusion of both: the Matrix Drive. This advanced configuration intertwines the best series and parallel designs, offering unique advantages for various applications. The image shows how to wire it up. In this setup, each row is shorted, creating individual paths for the current flow.

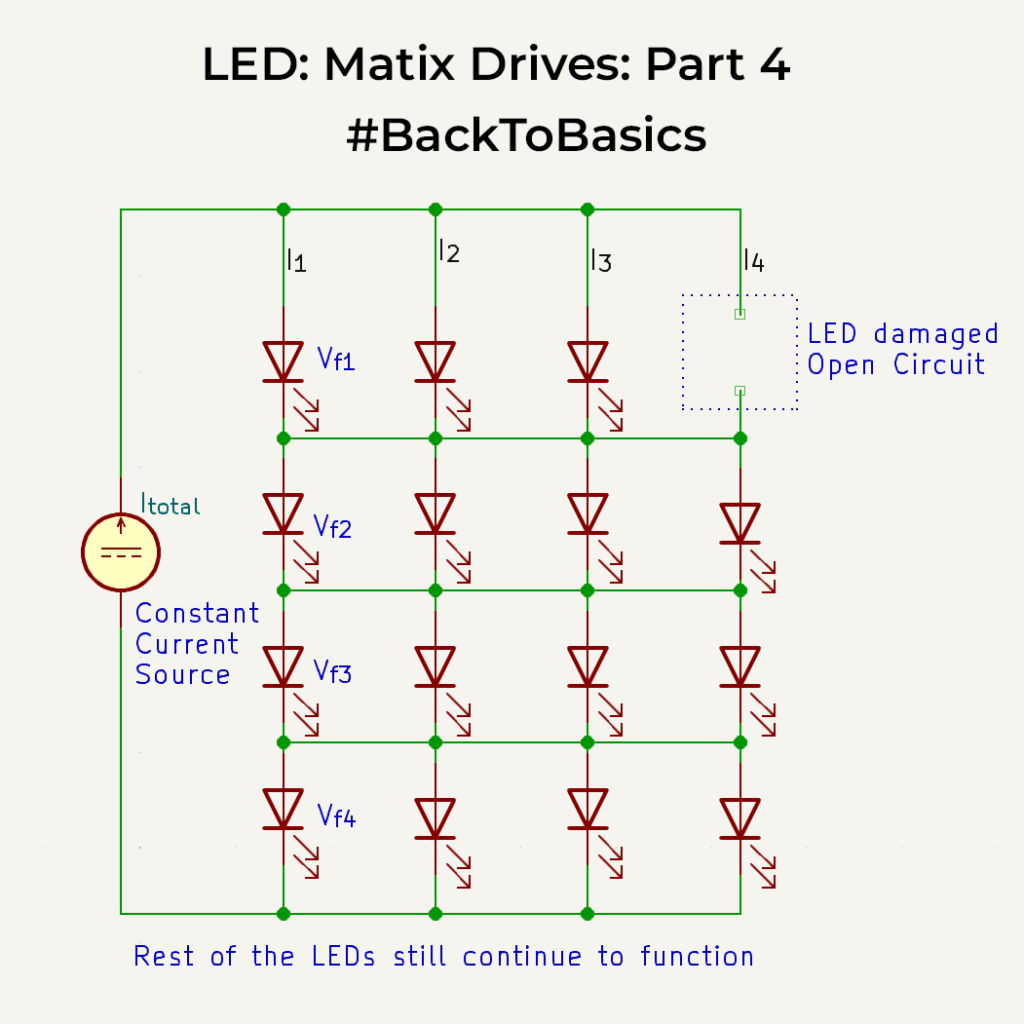

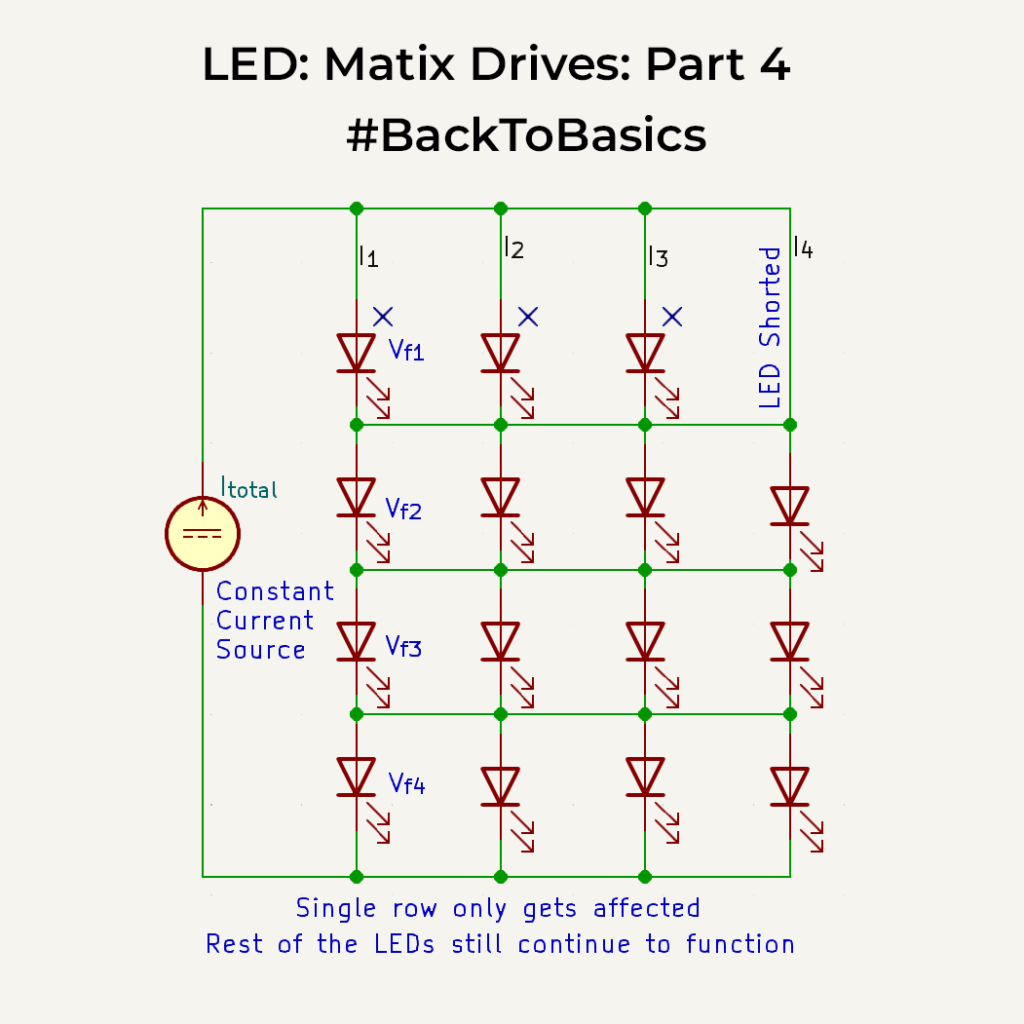

The advantage here is that, if an LED fails as an open circuit, the rest of the LEDs in the column are not affected as the current has a different path to flow. Current variation in arms is kept to a minimum. Now when an LED fails as a short circuit, the entire row turns OFF, but still rest of the LEDs in the columns are ON and with no increase in current per branch. So it does give you some sort of protection to avoid a chain reaction of all LEDs failing.

The major drawback of this method is that since there could be variations in Vf of the LEDs and each LED is in parallel to one another, you will see that the brightness intensity of LEDs won’t be uniform and there may be hotspots & dim spots in the lighting. So you have to choose LEDs with minimal Vf variation from the manufacturer.

Overall if you have no constraints over cost, series LED drives might be the best bet. If there are quite a lot of those LEDs, keep adding more series drivers. If cost is a concern(buck drives are cheaper) and you don’t have much concern with the lifetime of LEDs consider parallel drives. If you choose this, better to go with more LEDs in columns to reduce the current increase if one of them fails.

So now you know all about the nuances of series, parallel, and matrix LED drives and each has its pros & cons. Choose one based on your application and requirements. Happy designing!

0 Comments

Comments are closed.