Earlier this week, I was in a discussion with a client on piezo electric tech, especially about 2 pin and 3 pin types. I thought it’s worth a quick post to clear the most common confusions and when I would pick each one.

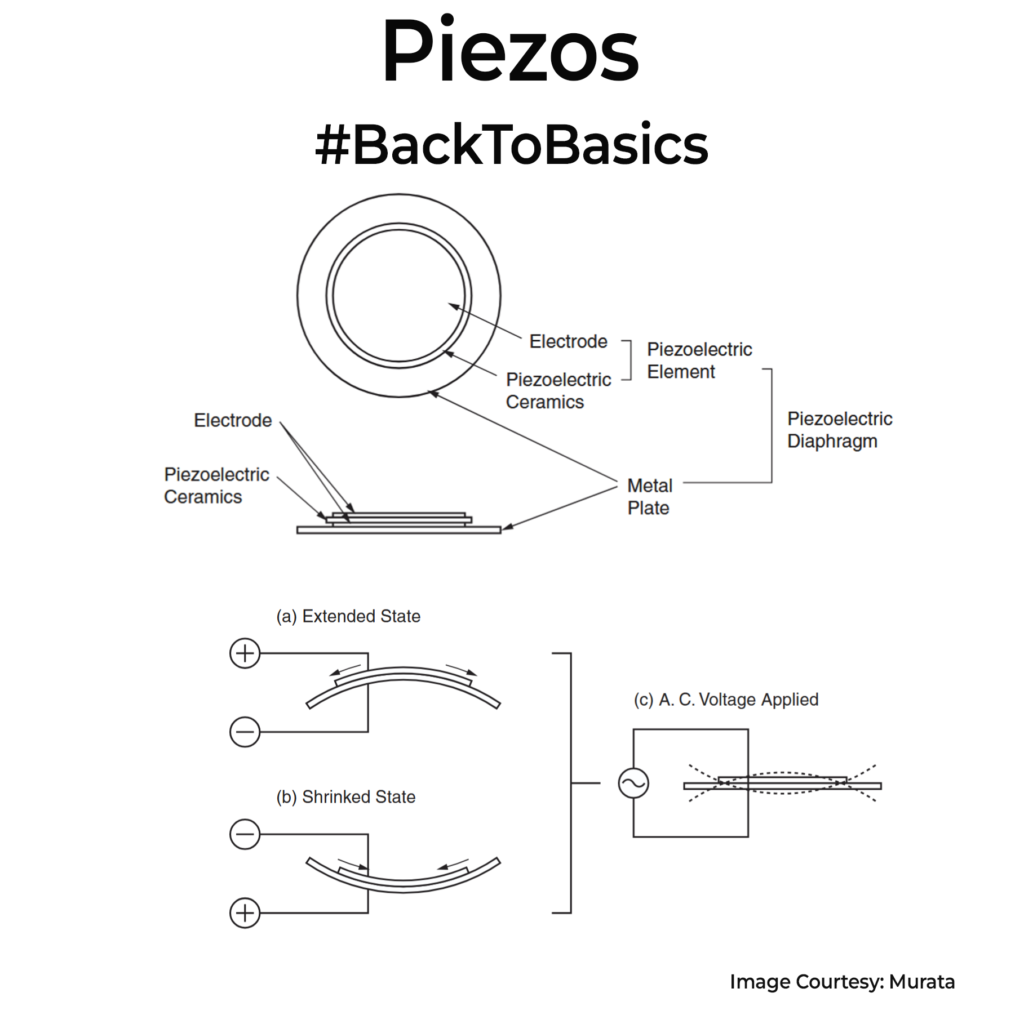

Simply put, a piezo unit is a thin ceramic disc with electrodes on both ends stuck on a metal plate. If you apply a DC, it deforms in one direction and if you reverse it deforms the other way. Now, if you apply AC, and it flexes fast, pushes air, and makes sound. Electrically, it’s just a small capacitor with a resonance in the few kHz range.

What I explained above is a passive 2-pin piezo. It’s a transducer disc with two electrodes. You must drive it with AC or PWM near resonance frequency of the disc. There is another type called the 2-pin active piezo. It has a built-in oscillator. Give it DC and it beeps at a fixed tone. Putting DC into a passive disc won’t make a sound.

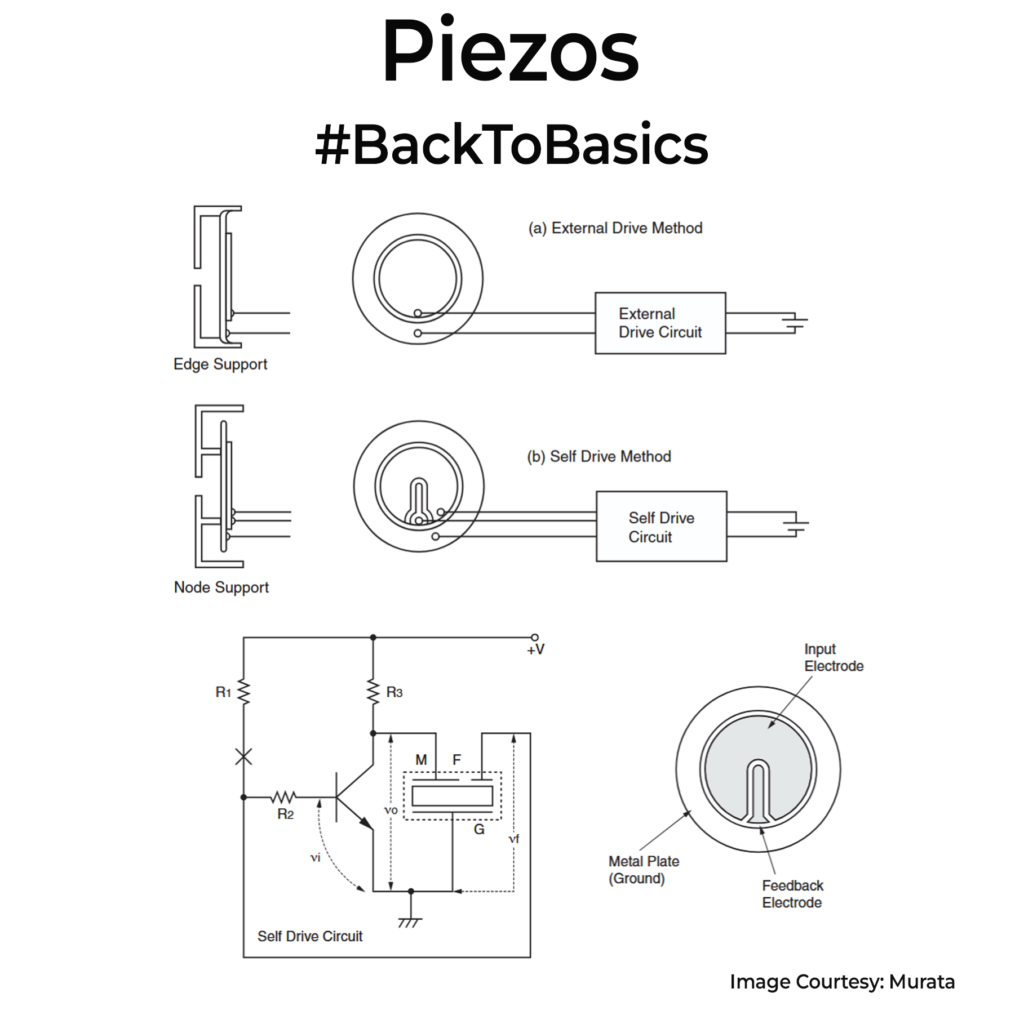

3-pin piezos are in two options. One is a three-electrode (bimorph) disc. It has an extra terminal called a feedback electrode. You can build a simple loop (check images) that senses the disc’s motion and feeds it back to sustain oscillation. The loop naturally locks to the true resonance of the disc and produces the loudest sound (So it’s used in alarms). There is no firmware or MCU involved so it is cheap. Since it’s “auto-tuned”, even changing enclosure will affect its sound output slightly.

The other is a 3-pin module. Pins are VCC, GND, and SIG. The element inside is still two-pin; a small PCB adds a transistor so an MCU pin can switch it to produce sound.

Anyways, everything above was about using piezos to create sound by pumping energy in and flexing the disc. The reverse is sensing. The same ceramic generates a voltage when you press, bend, or tap it. That means you can detect knocks, vibration, even airflow, and in some cases harvest energy from motion. I’ll keep this post focused on buzzers for now, but we can dive into piezo sensor front-ends, buffering that high impedance, filtering etc in the future.

0 Comments

Comments are closed.