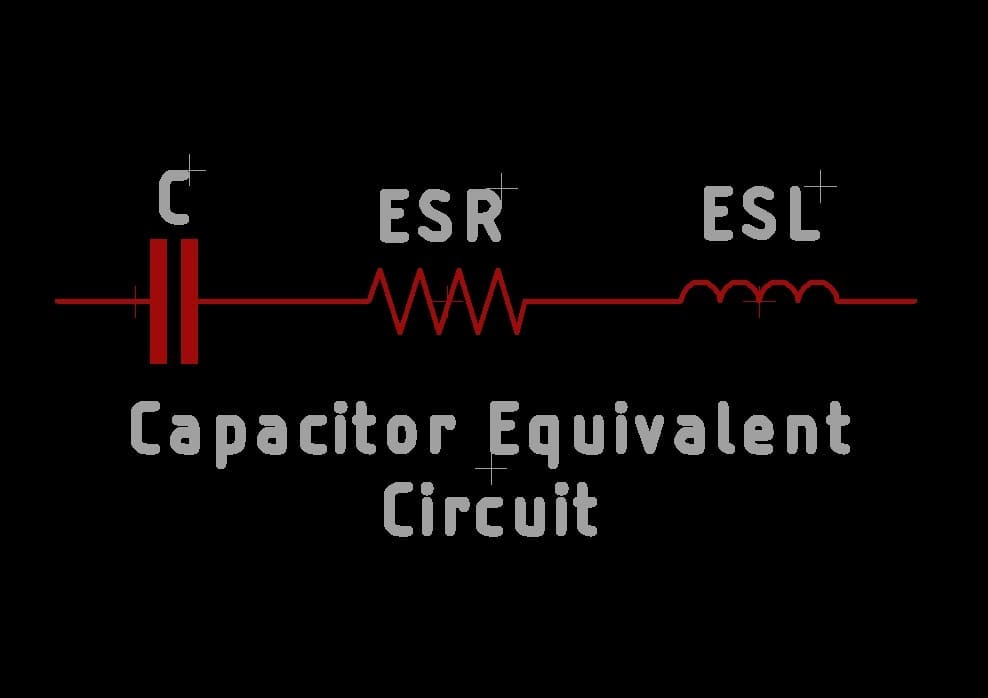

In real life a capacitor is not really a capacitor alone, it will have an internal resistor and an inductor. This resistance is what is known as an ESR. We ideally want ESRs to be tending to a low value as they are the primary cause of switching losses in a capacitor. These vary with the temperature and type of construction of the capacitors. Electrolytic caps usually have higher ESRs.

So why should you care about ESRs in your design process? Usually large electrolytic caps are used as bulk storage to maintain a voltage rail in the input of a system(To avoid voltage drops at high frequency). Now you have a high ESR capacitor, it won’t be able to deliver the charge to the system quickly because of the series losses in the ESR. That in turn will heat up the capacitor to potentially dry up the internal dielectric material as well. So in order to reduce the switching losses, try to use good quality capacitors with lower ESRs in your design if you have the budget for it. One trick is to use multiple caps of the same ESR, in parallel, to effectively reduce the ESR. High ESR caps reduce the longevity of your design with use.

ESRs are mentioned in the datasheets and is specified by measuring the resistance at a frequency of 100KHz. It’s done with an ESR meter which injects a 100KHz low voltage signal and measures the voltage across the capacitor to estimate the ESR(As at high freq, the capacitor will be having negligible impedance). This voltage is converted to resistance to give you the actual ESR of the capacitor being tested.

For circuit debug/repair work, ESR meters are a good tool to have because they can be used to measure ESR in-circuit(Without removing the part from PCB). If the ESR meter reads high(Usually bulgy electrolytic caps, but remember they need not be always bulgy), that’s a bad cap and you can remove that specific capacitor to replace it with a new one.