Anyone remotely associated with electrical systems would have seen a transformer. These tend to stick out as big rectangular-shaped units in your circuit and are called wire wound transformers. Most of you would have seen this in use in step or step-down voltage use cases for low frequencies(50Hz) AC power signals. They are built by wrapping enameled wire over a plastic part(bobbin) for both primary and secondary wires. Whenever there is a current change in the primary, there will be an induced current in the secondary. There are different types of ways by which you wind a transformer, but all of it is just to ensure that coupling is high between 2 sides and leakage is low.

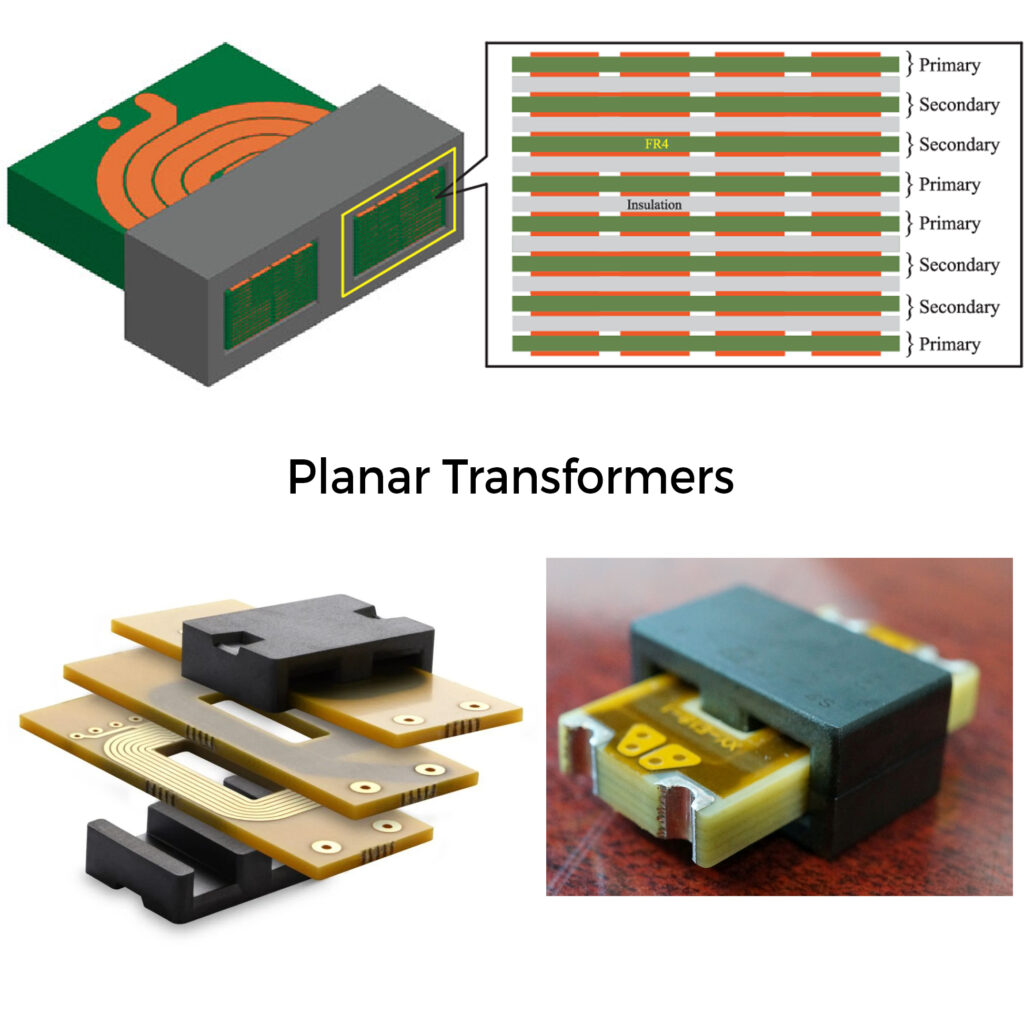

Now coming to high-frequency transformers, which are used in SMPSs, where the frequency of switching is several times larger. As freq is higher, you can use thinner wires(Skin effect, refer to older posts) This will help reduce the size of transformers. Now an even better way to reduce spacing(and increase coupling) is to ditch circular wires altogether and get them printed in PCB tracks. That’s exactly what planar transformers are. It’s a stack of PCBs with multiple layers with both primary and secondary current coils printed on them and connected in a certain way. Insulation is provided by the PCB dielectric and you can have more areas for better coupling. This ensures that the height of the unit is drastically reduced. Since these are PCBs, it has better heat dissipation ensuring that the transformers remain cooler. Manufacturability also goes up as it’s repeatable to make PCBs that are SMD mountable with machines than the older wire wounding semi-manual process. You can even create slots on the PCBs to mount your ferrite cores directly in it.

This is one of the key reasons for the size reduction in your phone chargers(refer to older posts). To learn more about the design and state of art of this tech, I would suggest watching a few videos on YouTube on the international workshop conducted by IISc this year. Search IWPMT 2023 for a series of talks on the same.