A friend of mine dropped off a pretty old pair of wireless Bluetooth Boat Rocker headphones which were not working. The power LED turns ON but it’s unresponsive after that. Opened it up and first did a charge test with a USB current meter and found that there was no current taken from the power supply. That’s usually bad news, as that could potentially mean that the battery is bust or the main chip is blown. I opened up the battery compartment and there was no bulging of the battery. The battery was showing voltage, which was slightly low, but nothing too concerning. Then I desoldered the battery and connected a spare battery right on the PCB. Then plugged in the USB meter and voila the new battery is charging. Turned out the culprit was a faulty positive battery wire running all along the headband. It had no continuity and it was broken in between. Replacing that thin wire should get the headphones backup. The device wasn’t turning ON as the main chip couldn’t detect the battery due to the broken wire, even though it was getting external power.

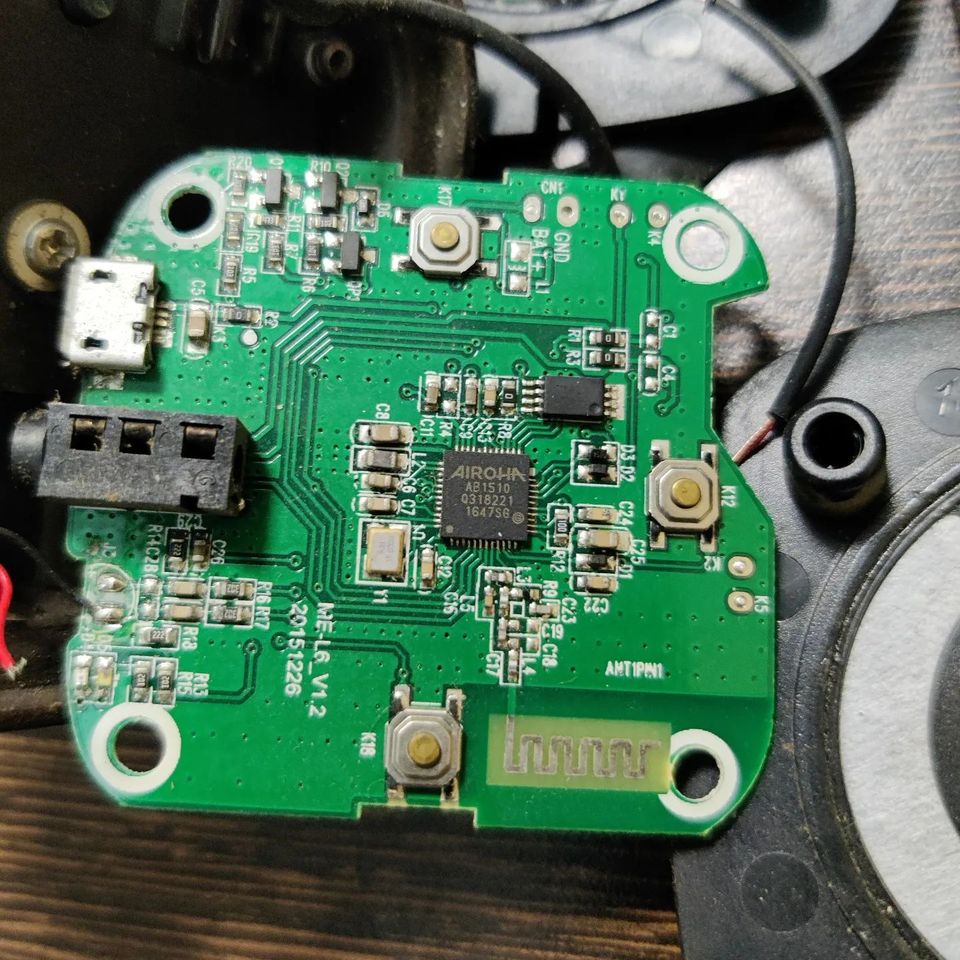

Coming to the circuit analysis, these BLE headphones contain a Bluetooth chip from the Taiwanese manufacturer Airoha (AB1510). It’s a DSP chip with 48MIPS. It has all the bells and whistles for audio input, processing and outputs. It has a BLE PCB antenna. The great part of this chip is a built-in battery charge controller capable of charging at 400mA with protection. This eliminates the need for an external charging circuitry altogether. I couldn’t find a pricing for these chips though. If anyone knows please do comment. The other main IC is 24C128A, which is a 2-wire Serial EEPROM from Microchip to mostly store audio presets I suppose. The LiPo battery has a capacity of 450mAh. All in all, a reasonably well-designed headphone.