To round up the ESD series, when you are going to choose your ESD protection device, you will see a lot of basic parameters that can confuse a designer. I have listed the major ones so that it makes life simpler for you when choosing ESD parts.

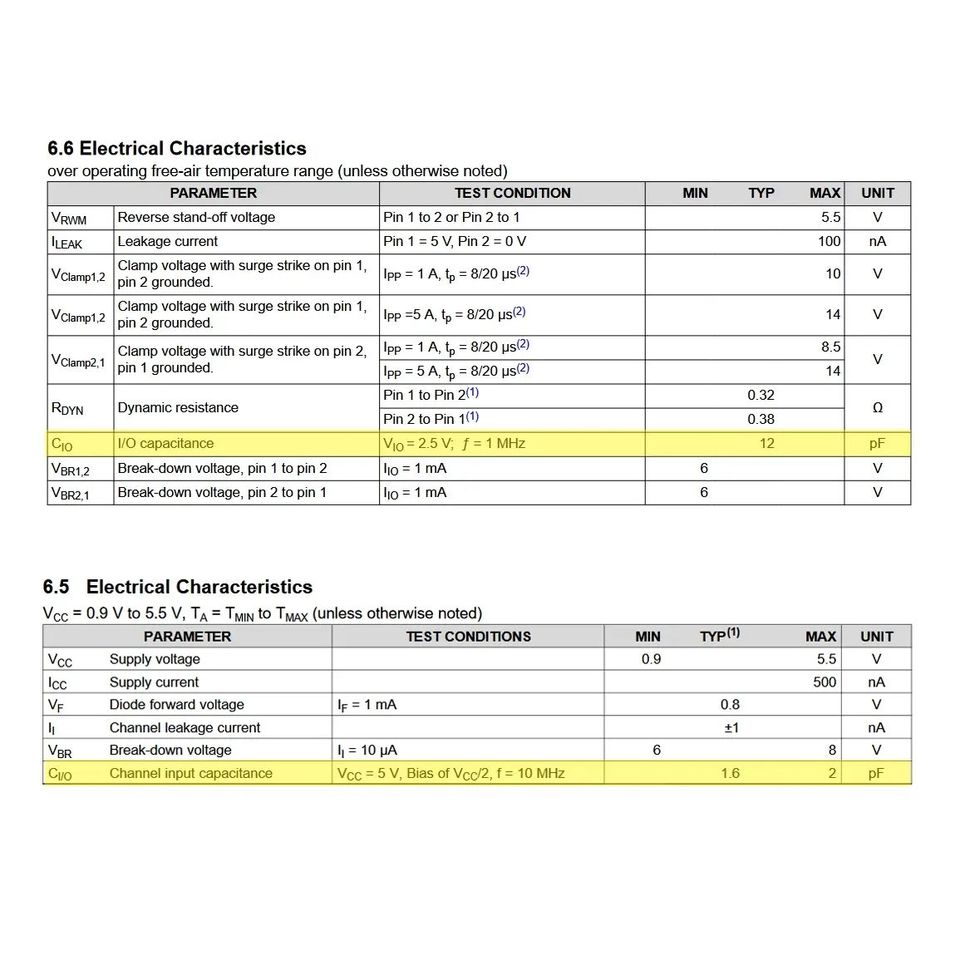

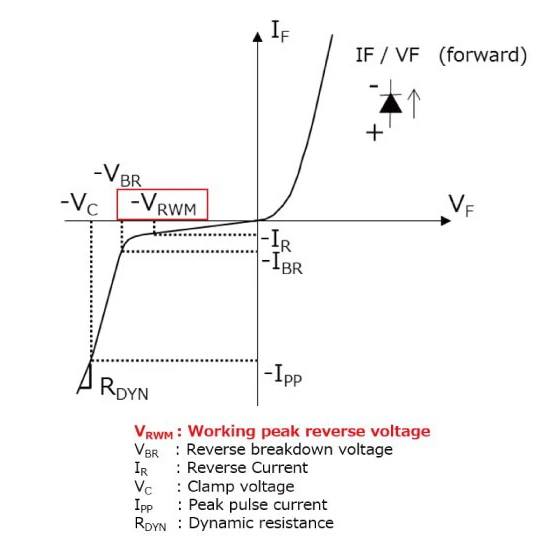

Maximum Working Reverse Voltage/Reverse Standoff Voltage: This is the voltage below which the diode barely conducts(Only leakage current). This is where your diode should be in normal operation. Always ensure that this voltage is above the normal working voltage of your line.

Minimum Reverse Breakdown voltage: This is the voltage level at which the diode begins to conduct and break down, typically 10-20% higher than the reverse standoff voltage. Again this value should be higher than the normal operating voltage of your circuit.

Dynamic Resistance: Its the resistance exhibited by a diode(after breakdown) when an ESD strike occurs. It’s the slope of an IV curve which you see in most datasheets. When choosing diodes, this value should be as small as possible so that the graph generated via TLP(Check prev. post) is steeper(To get a constant voltage at the output, when the current increases).

Clamp Voltage: This is the voltage that the ESD diode will show at its output due to dynamic resistance when an ESD pulse occurs. Its voltage the diode stabilises itself after the initial spike. This is very important as this is the voltage that your circuits downstream will see. Your downstream device should be able to handle this voltage for a small instance of time. This is where the problem arises as this value is usually not provided by the downstream device datasheet. You have to usually play a guessing game. Ideally, we try to get a clamp voltage as small as possible(higher than the normal voltage which it protects) when selecting ESD diodes.

Peak Pulse Current: Maximum current an ESD diode can pass before it’s damaged. It varies based on the IEC ESD protection levels a device adheres to.

Hoping this series of posts have covered the most important aspects of ESD protection, giving you a better understanding of how to choose the right ESD protection device for your circuits.