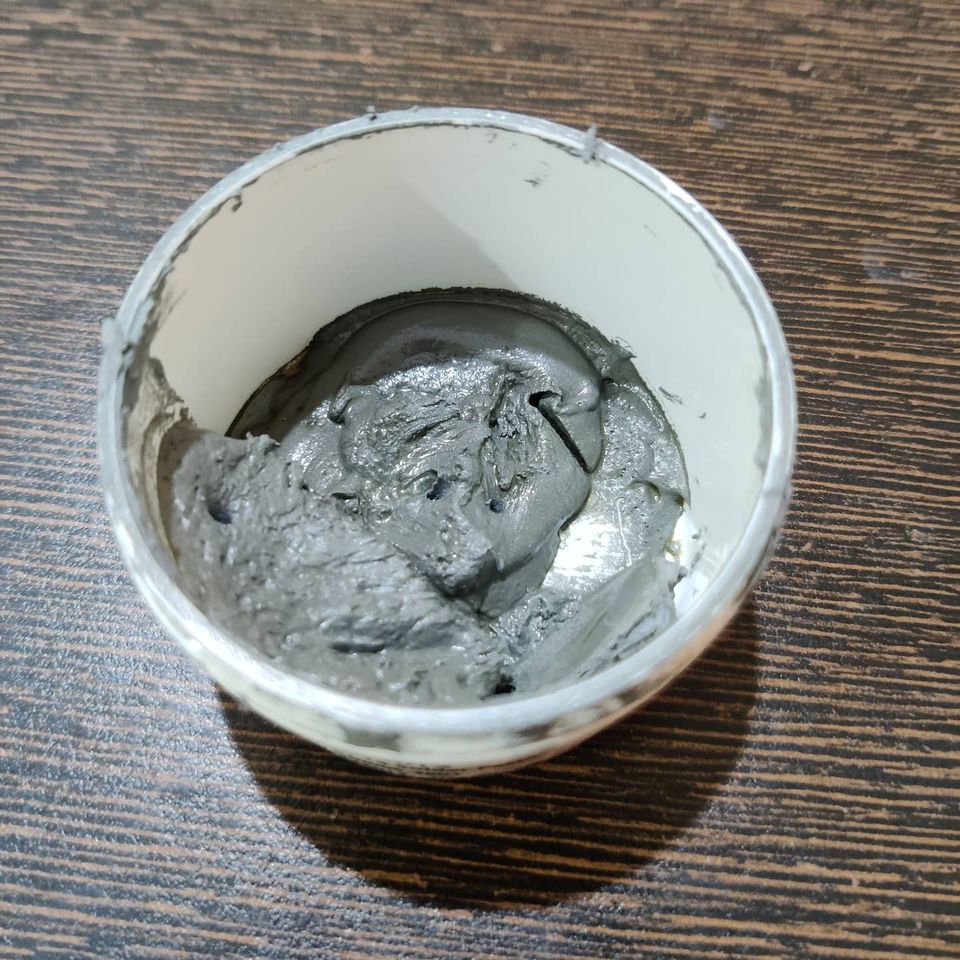

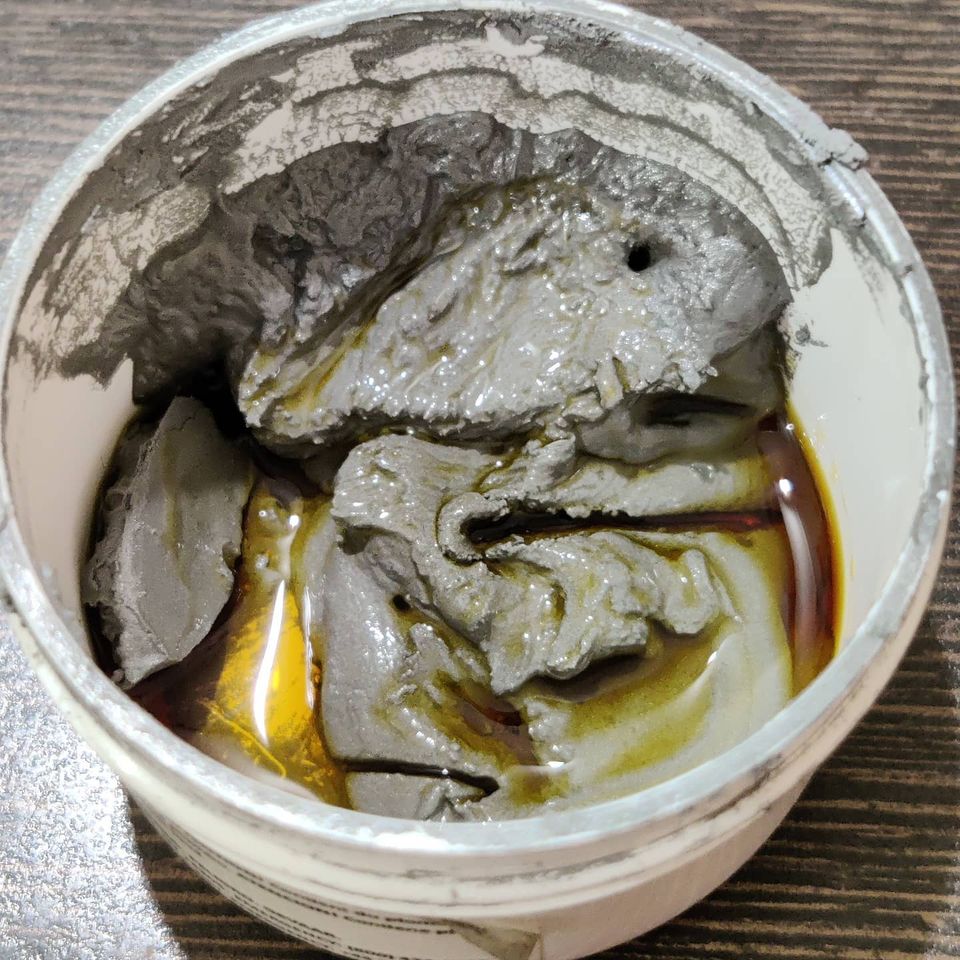

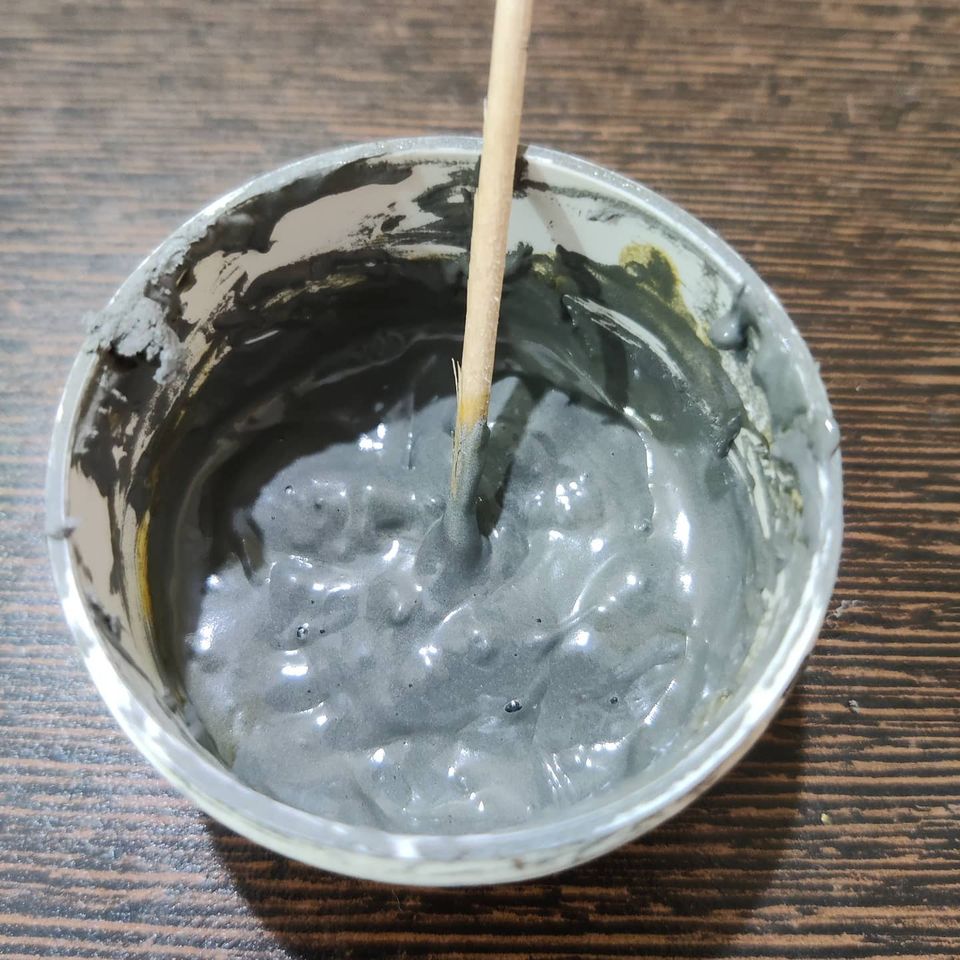

Pro Maker Tip: Have you ever had a tub of solder paste lying around which has dried out and doesn’t reflow properly? You don’t need to throw it away and can reactivate it easily. Pour a few ml of liquid rosin flux and mix it very thoroughly. Break the dried-out parts too and mix well. Solder paste will be back to normal for your soldering purposes. Add small amounts of flux initially to get the level of viscosity you want. (Might not be production quality solder paste but good enough for most applications)

Adding good quality high concentration isopropyl alcohol(IPA) also works, but the issue is that it will dry out again very fast.

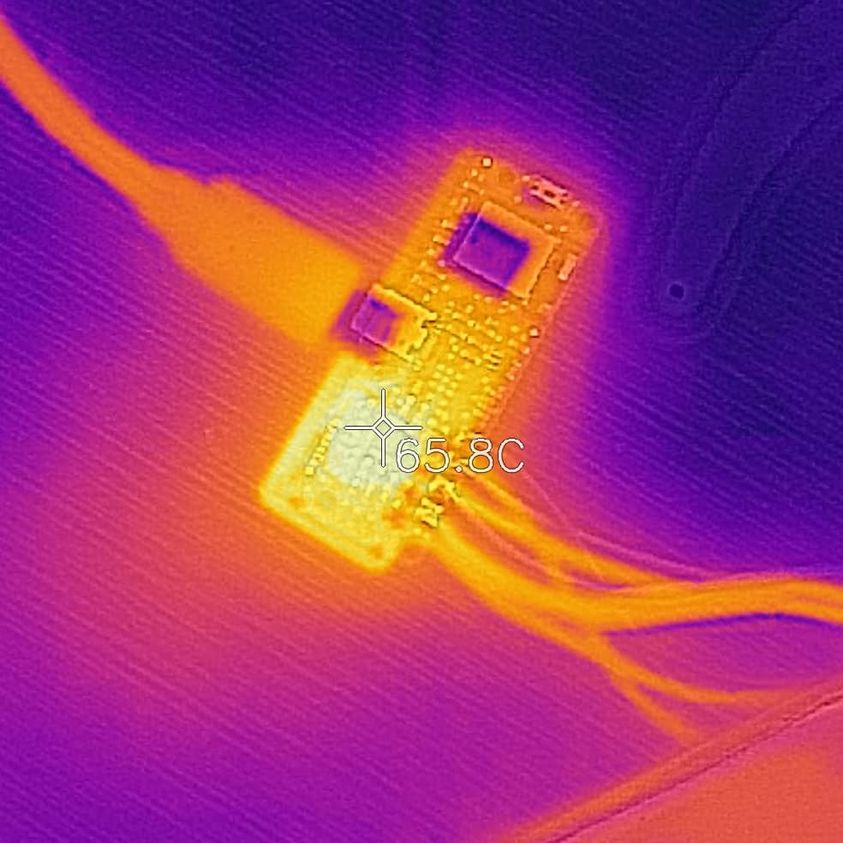

For those of you who don’t know, solder paste is just very tiny solder balls put in a chemical mixture to help with ease of spreading as a paste. It’s used for soldering surface mount components on PCBs.