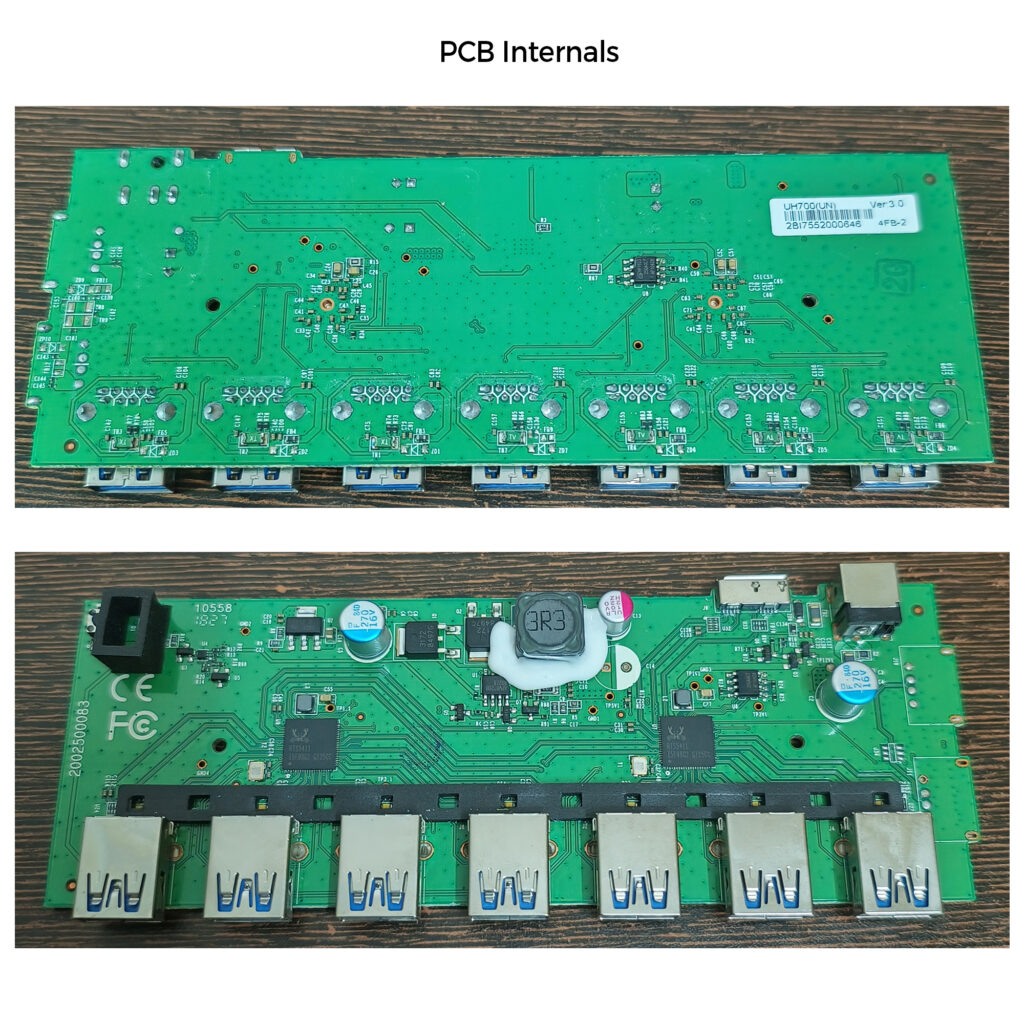

Haven’t done a teardown in a while. Had a TP-Link UH700 7-port USB hub in my scrap pile(But it was working). It’s a 12V powered USB3 hub with 7 ports and Micro USB3 input. After a solid 15-minute struggle, I managed to pry it open – those clips were tough! Needed multiple spudgers for the job.

Coming to the internals, the star of the show is two RTS5411S USB3.2 Gen1 4-port Hub controllers(In the middle row) powering 7 ports with a 12MHz crystal. The 8th port is routed as an input to the second RTS5411S. Firmware configuration likely resides in 25Q40CT SPI serial NOR flash chips located on both sides of the PCB. A convenient soft latch button rests on the top left. The power section on the top right and middle contains a 12V input jack and step-down buck converter APW8720B to put 5V through to beefy N-channel MOSFETs CED3172 and a massive inductor at the output. This chip fuels downstream 5V supply and an adjustable 1117 LDO supports the 3.3V rail. Each of the 7 ports has a PTC fuse protection to avoid blowing up if one port draws more current. There is a single LED to show if a port is active and the good part is that LEDs are optically isolated with a cheapo(but effective) black foam. There seems to be space for 2 more USB2.0 charging ports on the right which I believe is for a different Hub model with the PCB. Use the same PCB and sell it as a 9-port device. More Profit.

What’s intriguing is that every port has a footprint for an ESD diode array, yet none of the 8 USB ports, including the input port, have been populated. This seems like a risky approach and a strict no-no in my books. My assumption is that TP-Link might have used these chips on the certification test board to pass tests but omitted them in production to cut BOM costs. Though against the rules, this is a practice I’ve seen before in consumer products from other companies too. These units are likely to struggle with ESD tests. Has anyone in low-humidity environments faced ESD problems with this model?