It’s January and that means it’s time for CES launches. I am sure most of you would be tired of the CES coverage and overuse of the word “AI” over the last few days. When reading through many CES articles with the usual tech upgrades, I found a small gem that didn’t get much attention.

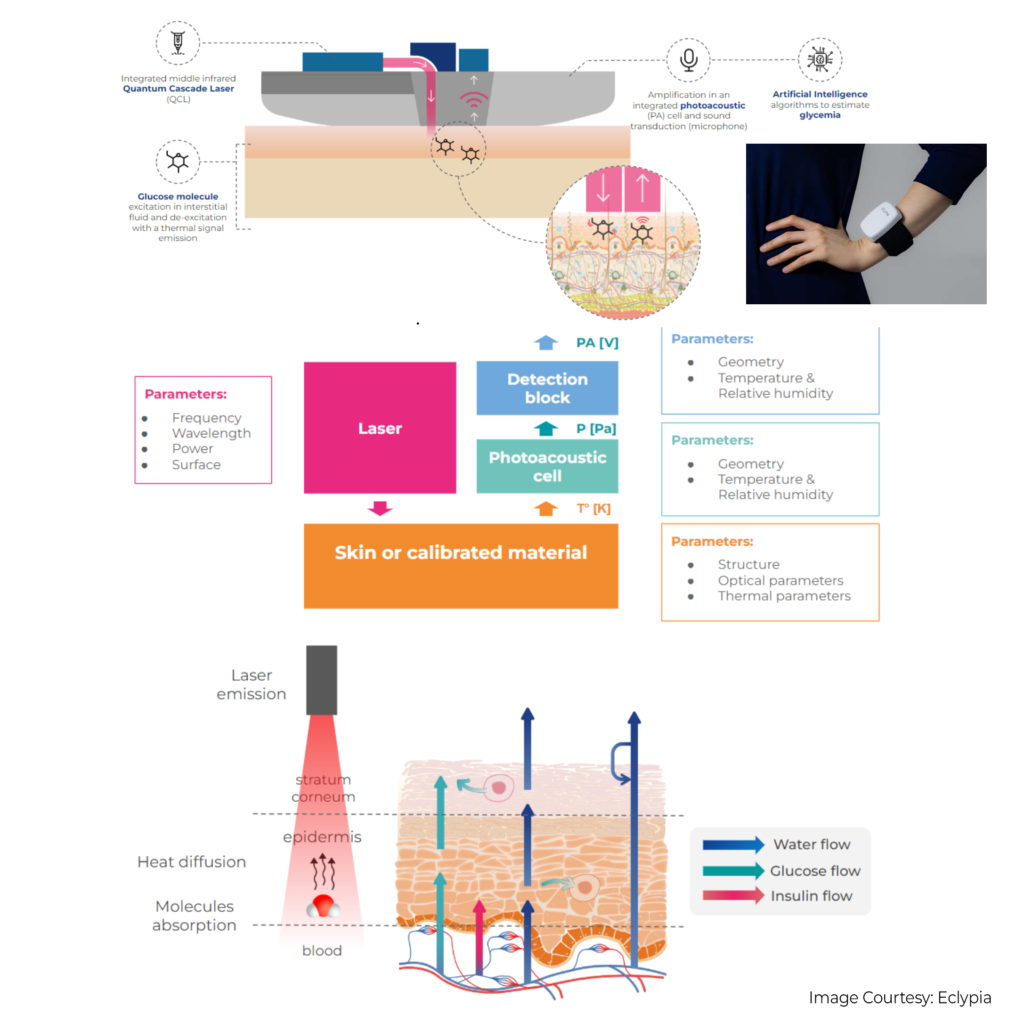

The company is called Eclypia which is into developing non-invasive reliable continuous glucose monitors. An accurate non-invasive glucose monitor is supposed to be one of the grails of medical tech problems many companies are trying to solve. The current state of the art is still pinprick blood draw or a prohibitorily expensive needle patch which needs to be replaced often. So folks with diabetes are still looking for solutions that can measure their glucose levels.

According to a white paper by Eclypia, the wearable device has infrared red lasers illuminating the skin. This excites the glucose molecules in the skin, which creates a thermal signal as they return to their normal state. This signal is amplified by a photoacoustic cell and then picked up by a microphone. So they have only tested this in a digital twin in an in-silico or a simulated computer clinical trial. They use this simulated clinical trial to create a synthetic dataset to fine-tune their deep-learning algorithms. I see that they have registered for a few in-person clinical trials online. The full results of it are not out yet and the paper claims a promising error rate of 18.4%. I wish them all the best for a larger clinical trial. It’s high time that someone finally cracks this problem once and for all.

What was your favourite CES tech this year?