When ICs & PCBs became smaller and smaller, thermal management became a big deal in circuit design. It’s one aspect that heavily impacts the lifetime of the product you are designing. The reliability of a product drops in an inverse-squared fashion as temperature increases.

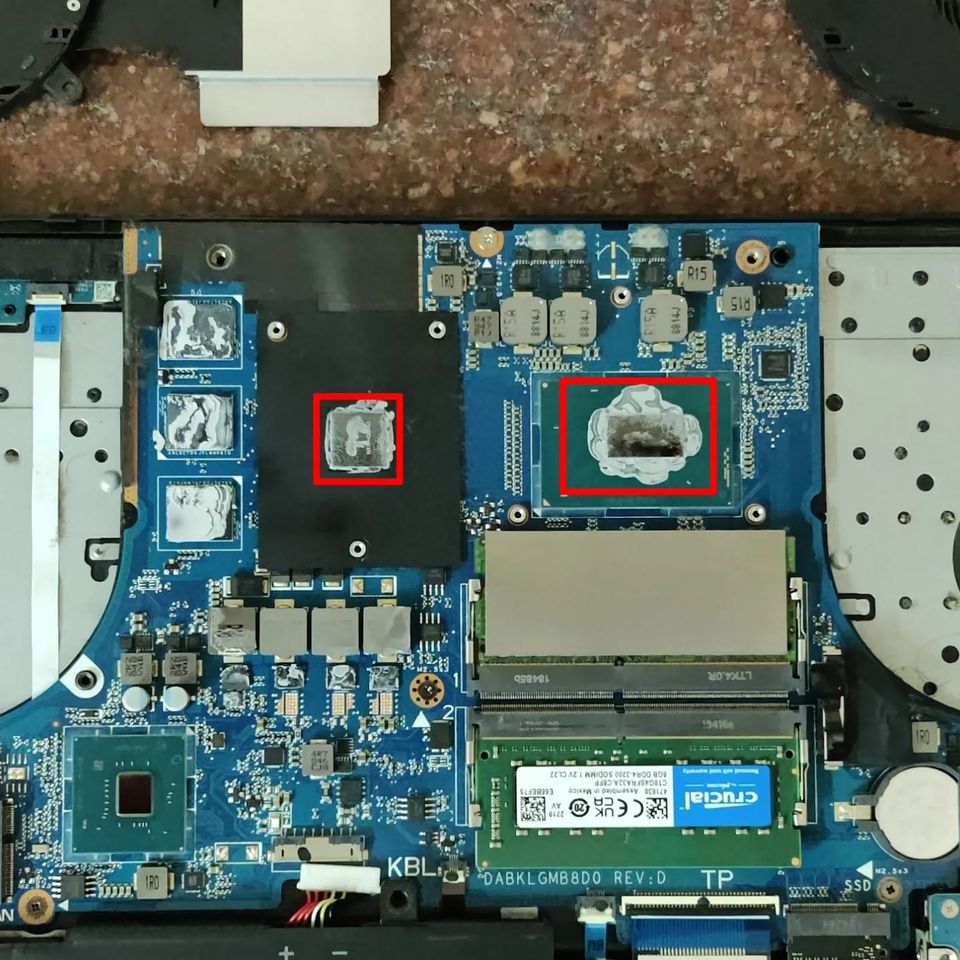

Last week my laptop was showing the classic Windows Blue screen of death intermittently. Initially, I thought it was a Windows software issue, but a bit of snooping around made me realise the processor cores were heating up. This is a common problem with laptops as it ages. What usually happens is that the thermal compound which is used to transfer heat from the processor to the heatsink dries up and its thermal resistance increases drastically.

Thermal resistance, as the name implies, is the amount of hindrance a part provides for heat dissipation. It is measured in Kelvin per Watt. What it means is that, for 1 Watt of power passing through the device, how much will that part heat up on the Kelvin scale. A larger number means it is pretty bad at conducting heat. All processors will be connected to a heatsink for heat management. These two are 2 solid surfaces that won’t have flush mating surfaces. The thermal compound is the key element that facilitates this gap-filling and helps in the efficient transfer of heat. In the PC build domain, there are tons of info online on which thermal compounds you must use, so I won’t go into details about that. In the end, it mostly boils down to a factor mentioned as thermal conductivity. Larger the conductivity, the better the heat transfer. It’s measured in Watts/Kelvin. When buying thermal compounds, pick the larger one in your budget.

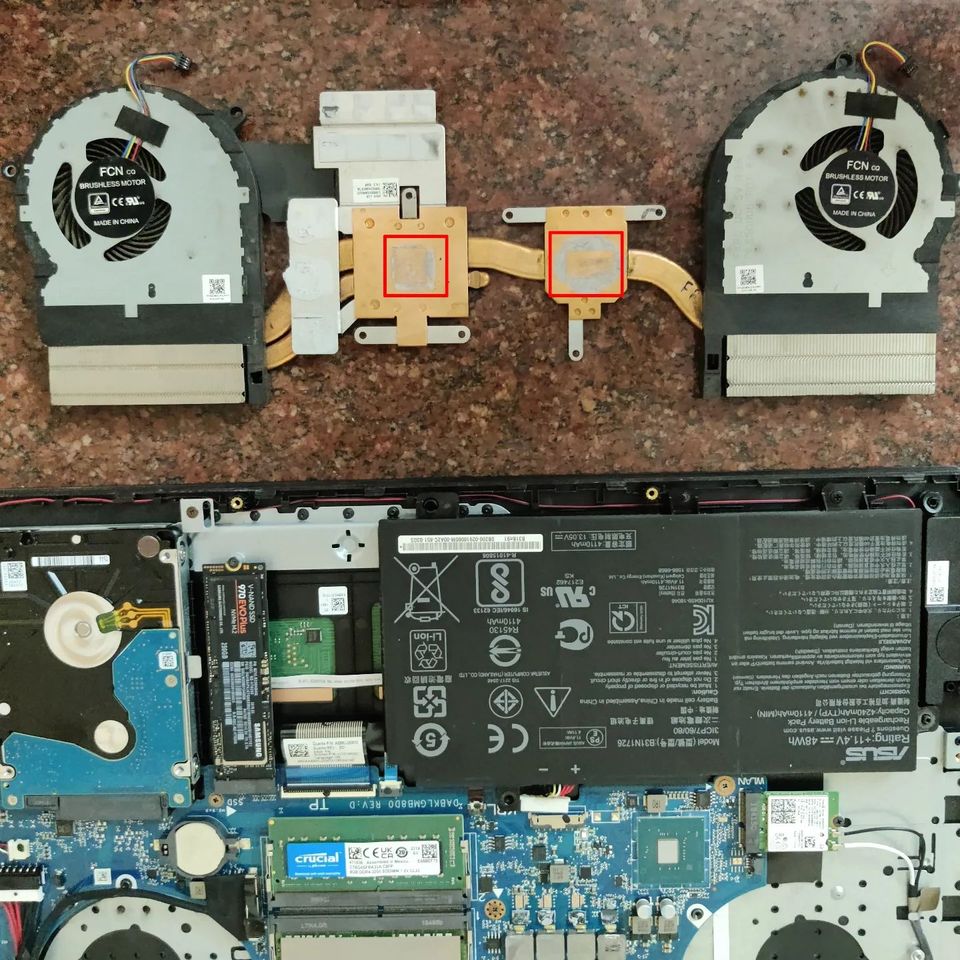

Back to the laptop heating problem. Well, the solution to the problem is fairly simple. You need to dissemble the laptop and remove the heatsink. Thoroughly clean the old thermal paste with isopropyl alcohol, then apply the new thermal compound and put everything back. I saw all my CPU cores running at approx 10°C cooler after I changed the thermal compound and no more crashes. If you are having performance issues, this may be something you can try.