Most circuit designers would have used heatsinks in their circuits to dissipate heat generated by Regulators, MOSFETs, Drivers, etc. Heatsinks are used to dissipate heat to the surroundings whereas heat pipes are designed to transfer heat from one region to the other where cooling can take place. It is used in spaces where there is not enough space to have a large area of heatsink right next to the heat source. You would probably have seen them as closed copper-coloured tubes on processor heatsinks or inside laptops.

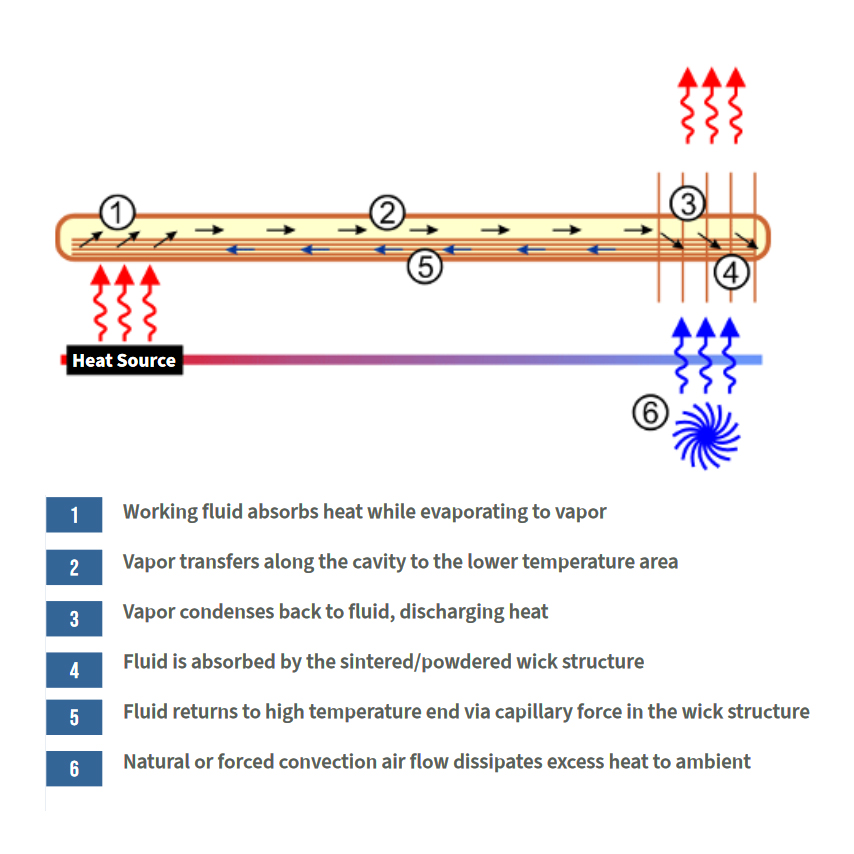

At their most basic level, heat pipes are simply sealed tubes filled with a liquid that is designed to absorb and transport heat. When one end of the heat pipe is exposed to a heat source, the liquid inside the tube absorbs the heat and evaporates into a gas. This gas then travels down the length of the tube to a cooler area, where it condenses back into a liquid and releases the heat it has absorbed(Via a heat sink or fan or any cooling mechanism). The liquid then flows back to the hot end of the tube by a wick. What makes them extremely good is that they have a very large(at least 10x) thermal conductivity than that of a pure metal block like Copper or Aluminium because the liquid inside can change to vapor and carry heat faster. They rely on evaporation on one side and condensation on the other side. They can also operate over long distances, allowing heat to be transferred away from critical components to a remote location.

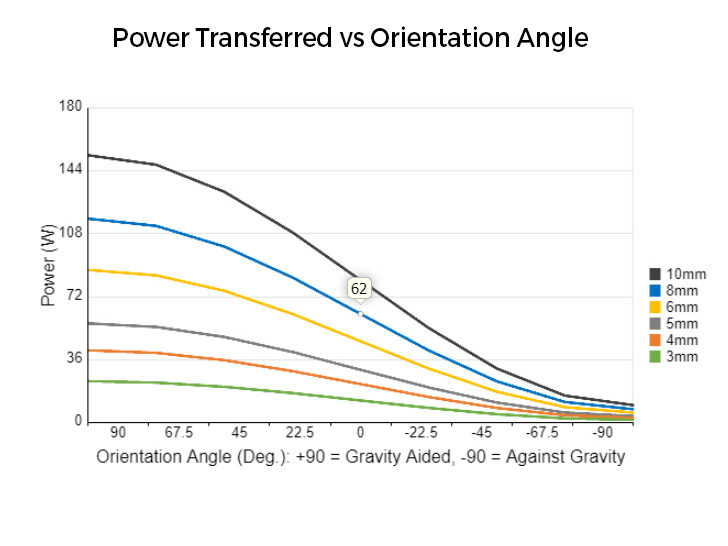

Heatpipes do come with a drawback, since it relies on fluid moving from a colder section to a hotter section in the liquid phase via wicking, their performance of heat transfer drops significantly if it’s made to work against gravity. If you see the charts you will find that how heat transfer properties fall as you change the orientation angles. So, when using heatpipes, it’s important to consider the orientation of the product to maximize heat transfer

For more Recommended Reading: Wakefield Thermal Design guide, ACT Cooling & Celsiainc website