Yesterday I was doing some research into display drivers for a project and got to learn about how the TV displays evolved. One of the things I learned was contrary to popular belief, it’s not pixels – it stands for “progressive.” Let me explain.

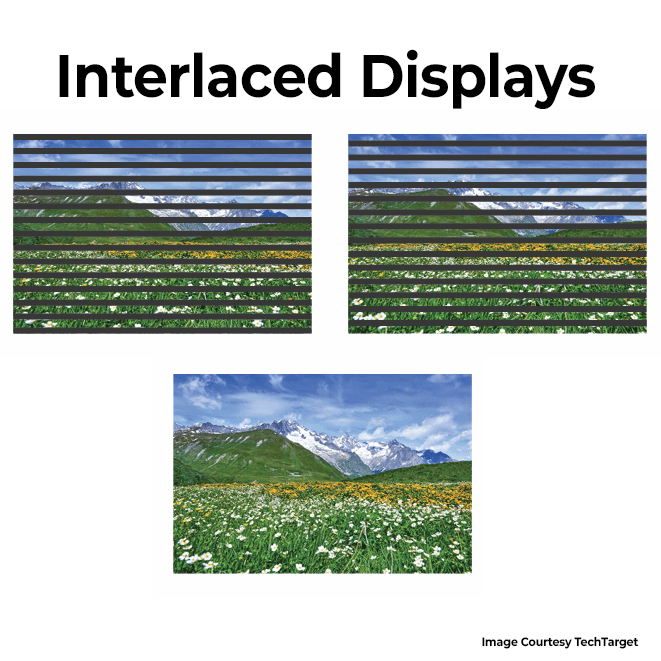

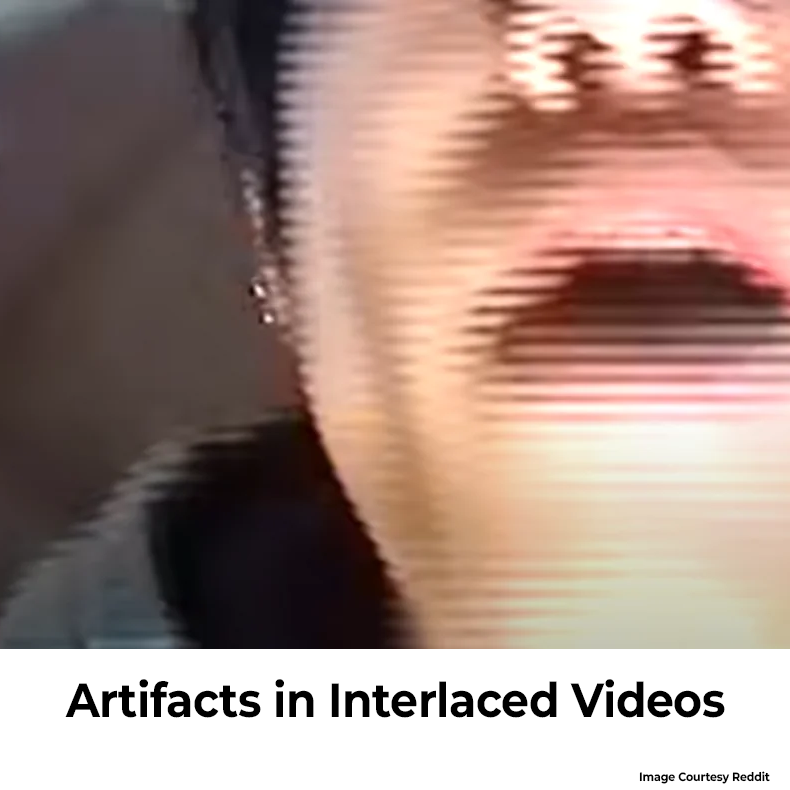

The “1080” part of 1080p stands for the number of pixels in the vertical direction of your display. It can be 720, 1440, 2160, etc. When you are trying to display something on a screen(called “scanning” the screen), there are 2 ways of doing it. Interlaced scan and Progressive scan. In an interlaced scan, the image to be displayed is divided into two fields, and only half of the lines are shown at a time. The first field includes the odd-numbered lines(1,3,5,..,1079), and the second field includes the even-numbered lines(2,4,6,…,1080). These fields are then displayed alternately to create a complete frame. Meaning, that at a single time, only half the screen is refreshed to a newer image. This was done in the olden days of CRT Displays to show higher-quality images on screen with only half the bandwidth. It reduced the transmission rate needed for videos. But this has drawbacks for fast-moving scenes, you may observe some stripes/artifacts in the screens for these videos.

Now Progressive scans, on the other hand, displays or “scans” every 1080 lines one by one, top to bottom, and refreshes every pixel on the screen at the same time. That means full bandwidth is needed to show a frame. Progressive scan provides a smoother, faster, and more detailed image, making it a preferred choice for modern displays. You don’t find interlaced formats that much these days.

Now you know what “p” means. Who knew pixels could be so progressive? ????