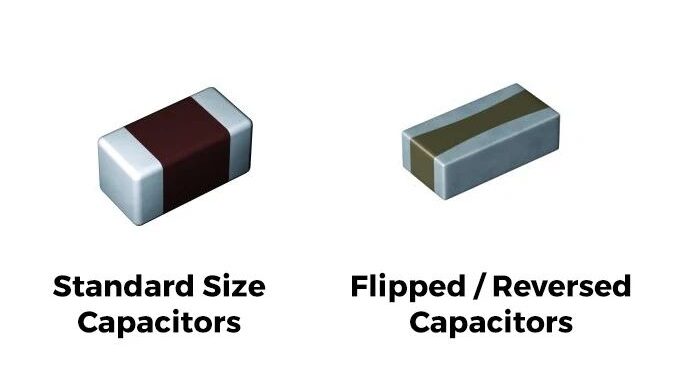

Most electronic design engineers know SMD capacitor parts come in the “standard” sizes of let’s say 1206, 0805, 0603,0402, 0201 etc. The common element of these parts is that their size is longer along terminals(between 2 pads you actually solder) than along the width of the part. Most times width of the part is half the length. There is a different class of capacitors which are wider than long. These are called flipped or reverse geometry capacitors. So the sizes will be 0612, 0508, 0306, 0204 etc. (To be honest, you might not find a flipped capacitor for every “standard” size capacitor though)

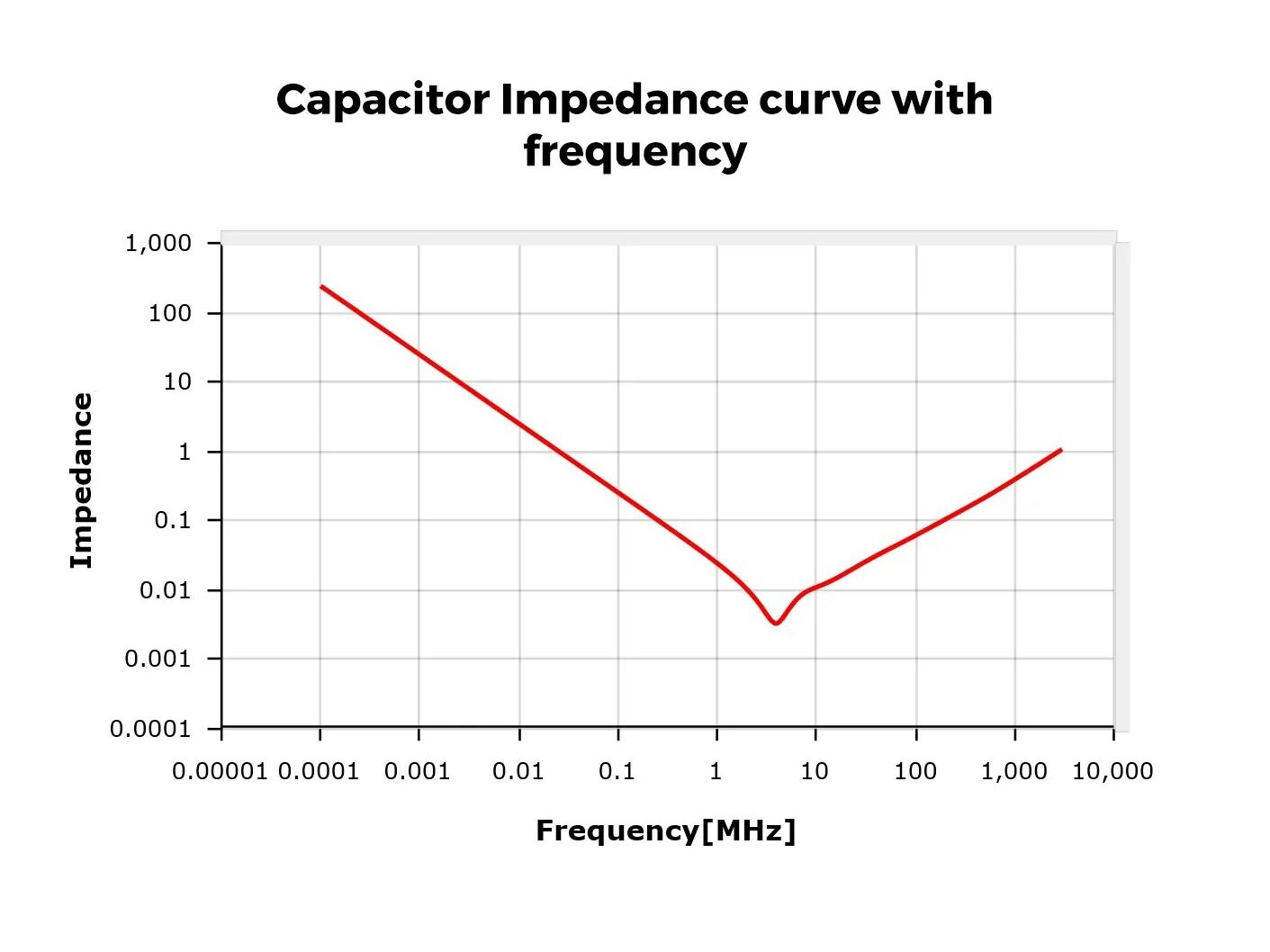

Why do we want to use a flipped capacitor? In one of my older posts, I explained that a capacitor in real life is not a capacitor by itself. It has an equivalent series resistance(ESR) and inductance(ESL). For an ideal capacitor, we would want to have ESRs and ESLs to be zero. Since there is an ESL in a capacitor, you usually see a V-shaped impedance curve with frequency in capacitor datasheets. The impedance value keeps getting low till a point and then it increases due to ESL. Here is where flipped capacitors come into the picture. Flipped capacitors are designed specifically to reduce ESL. When you flip the width and length dimensions of a capacitor, it reduces the soldering pad distances(or the length). Lower travel length means lower inductance and lower conductor length(Not to complicate it more, loop area also reduces, which is a good thing). So current needs to travel a shorter distance. A wider flipped capacitor effectively can have an impedance curve which is similar to 3-4 same standard-size capacitors. That means overall lower BOM count and layout space is lesser. For these reasons, these wider capacitors are starting to gain acceptance in the PCB design space.