Continuing with the isolator series, digital isolators were designed to remove the 3 major flaws of optocouplers: slower transmission rate, higher power consumption and LED derating problem for longer life. Digital isolators(although it’s an overarching word) are usually built on CMOS technologies and use magnetic or capacitive coupling to transfer digital signals across the isolation barrier. The input and the output side, are separated by an isolation barrier.

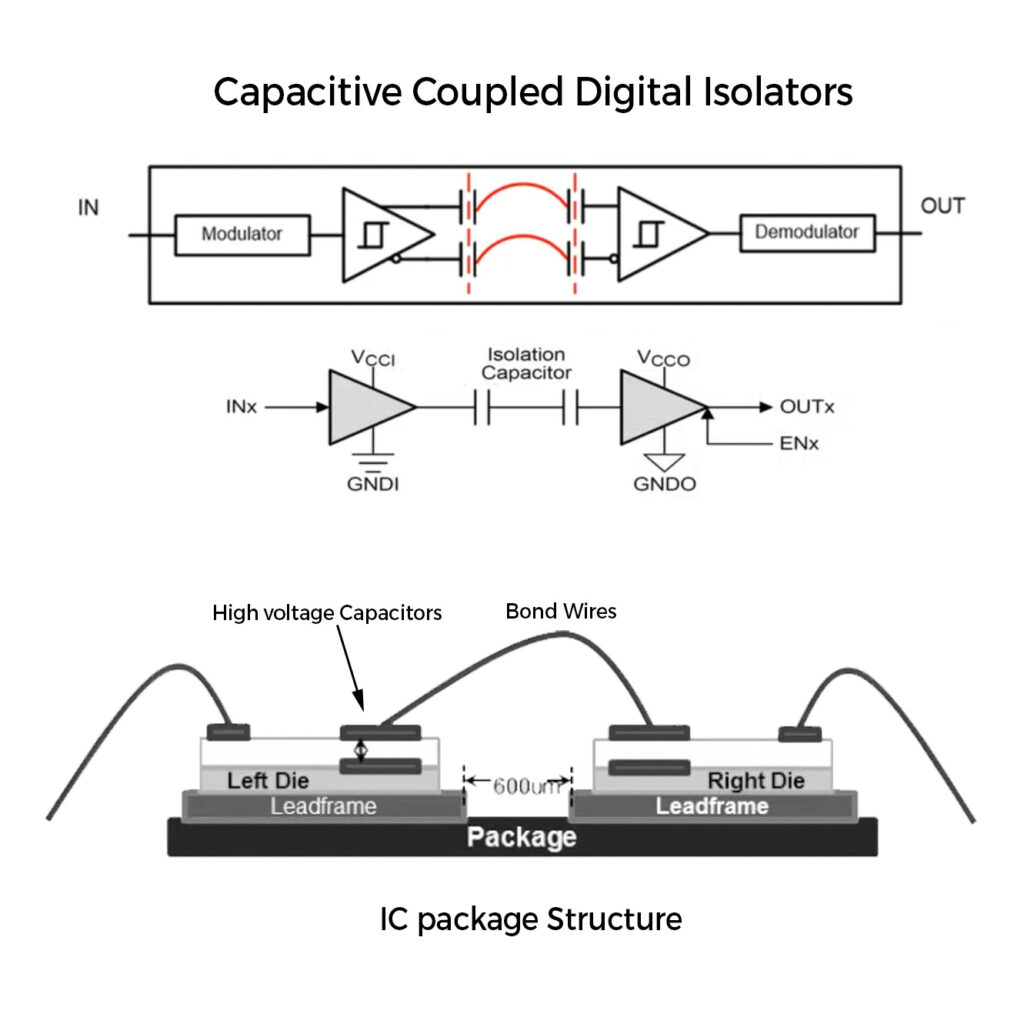

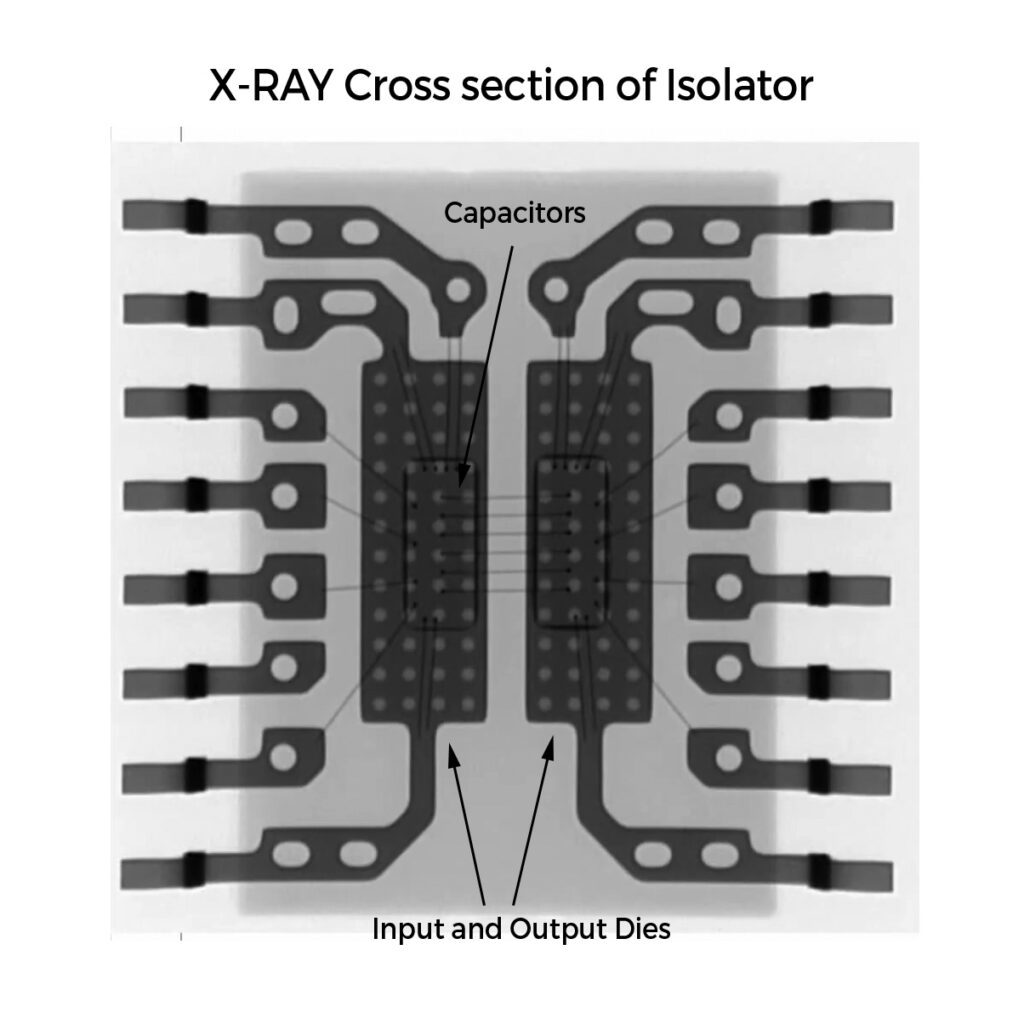

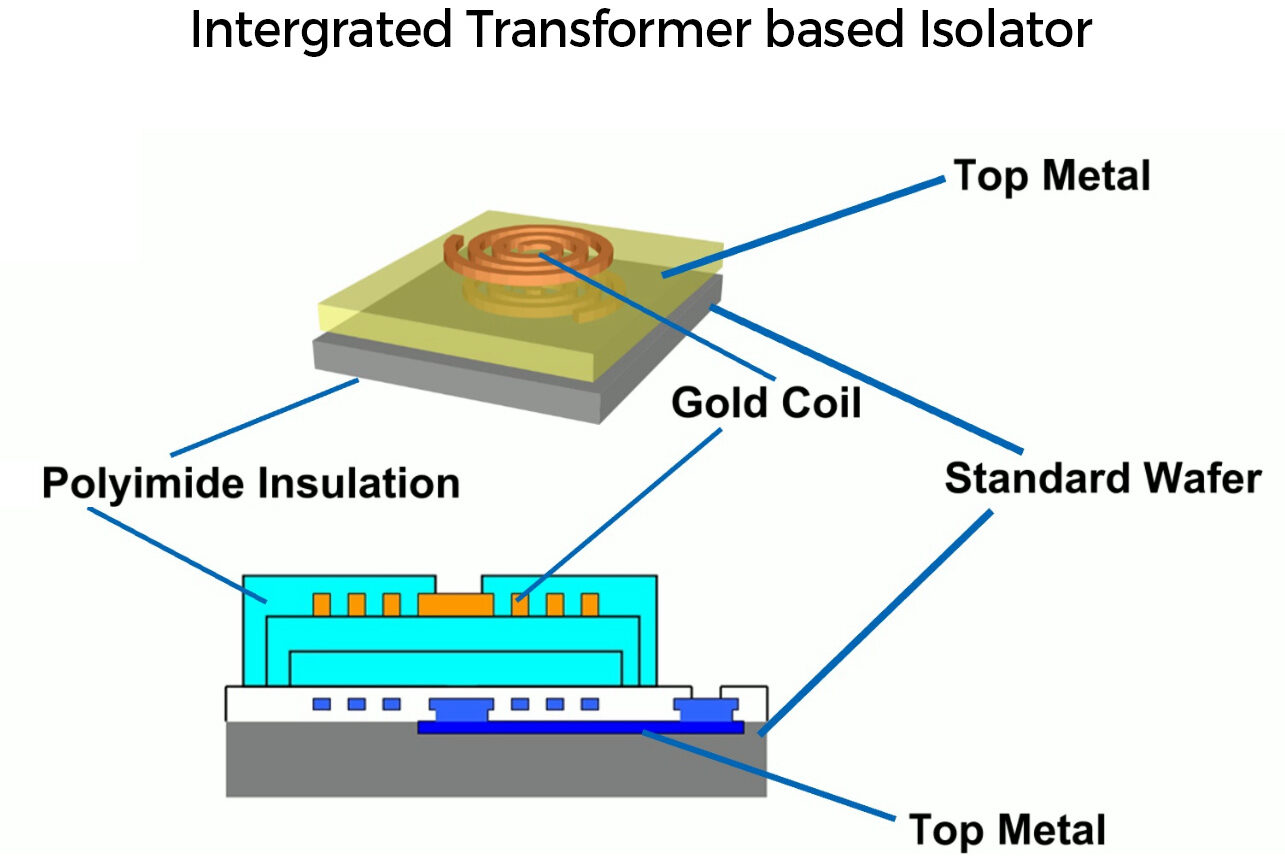

Let’s see how they transfer data. Inside the IC, The input and output sides are made on 2 separate dies(Check images) on the same IC and there is a physical distance(>0.5mm) providing isolation. Capacitive coupling uses two conductive plates separated by an insulating material to transfer electrical energy between two circuits. The input digital signal is modulated to a higher frequency and is passed through via isolation capacitors(one on each side) on the silicon dies. On the output side, these are demodulated to get the input signal back. The two sides are powered with separate voltage sources with no common feedback loop. Wirebonds run the signal between two halves. The use of SiO2 as the dielectric material provides great. isolation. Another type of digital isolator comes with integrated transformers built into the ICs providing data transfer via magnetic coupling across the isolation.

When to use them? From a performance standpoint, digital isolators outperform optocouplers in terms of faster transmission rates, lower power consumption, longer lifespan, and ability to operate in harsh environments. Although digital isolator technology is relatively new (around the last 15 years), compared to opto-based technology which has been around for a long time, the relative cost of optocouplers is cheaper than other digital isolators. Therefore, during the design stage, it is important to balance the benefits of digital isolators against their cost. If cost is not a major concern, it may be worth considering digital isolators for your application.