Every once in a while I have been split in my mind about how to route PCBs. There is the current “standard/professional” way of doing it or you can do it using any-angle-routing/curve-routing. To give you a bit more context, the standard routing practice is when you route a PCB on a grid-based board on your favourite CAD tool and you do bends at 45/90 style and all lines are straight and point-to-point. Whereas in curve routing, you bend and turn any different angle and you can smooth it out as if you are doing a free hand drawing. Newer folks in the industry do think that curve routing is absurd.

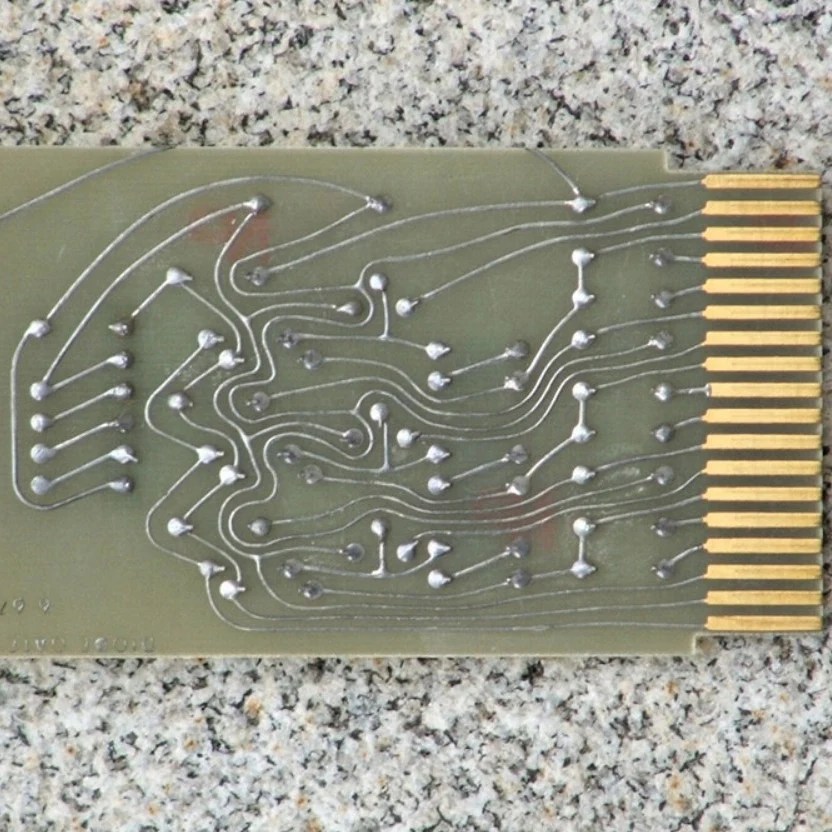

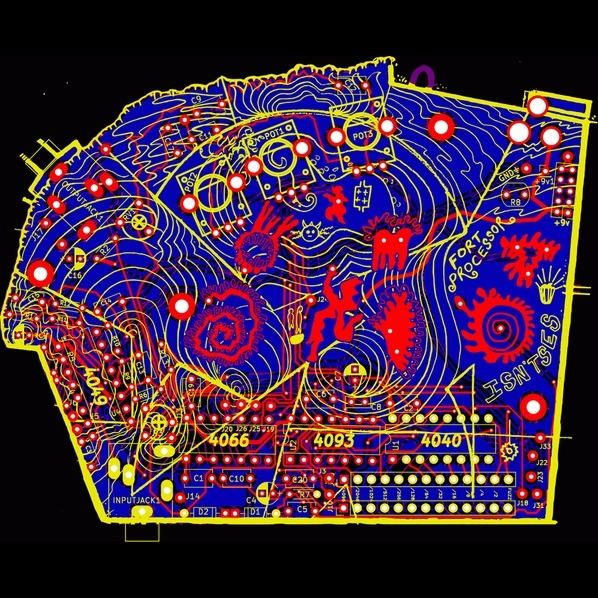

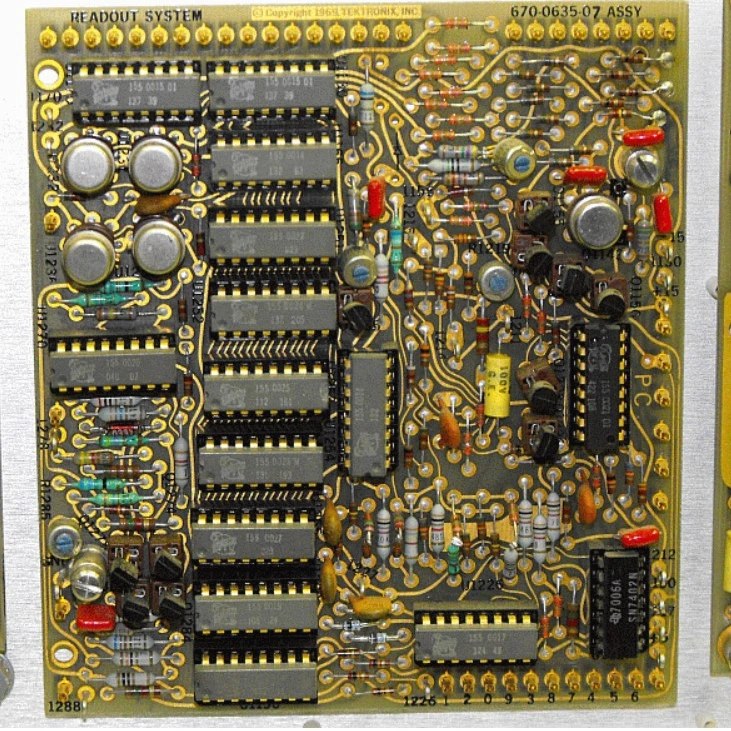

A common issue raised against curve routing is that it looks “ugly”. Even I thought so initially, but when I started questioning, Why does it look ugly? I started to realise its just because it’s different from thousands of boards design which I see out there. My mind is conditioned to think that it’s “ugly” because my “normal” is defined in a certain way. Heck, it doesn’t look organised but it works. There are benefits for curved routing too, like shorter routes between points, lesser impedance discontinuities(in high GHz), and more compact routing as you are not constrained by the grid or angles. Before the age of CAD, folks used to do hand routing of PCBs exactly like this. When CAD became grid based because of the compute-complexity of drawing real-time traces, it shifted to 45/90 routing.

These days although it’s not easily available in all CAD software, some CAD software like Altium(built-in) and Kicad(with a plugin), Topor(with excellent auto-routing capabilities) do provide these options but everyone(including me) keeps using the “standard” way. I do keep wondering if I can ever remove this mental block and adopt it.

Would love to know your thoughts on this. Would you ever use curve routing? Why do you prefer one over the other?

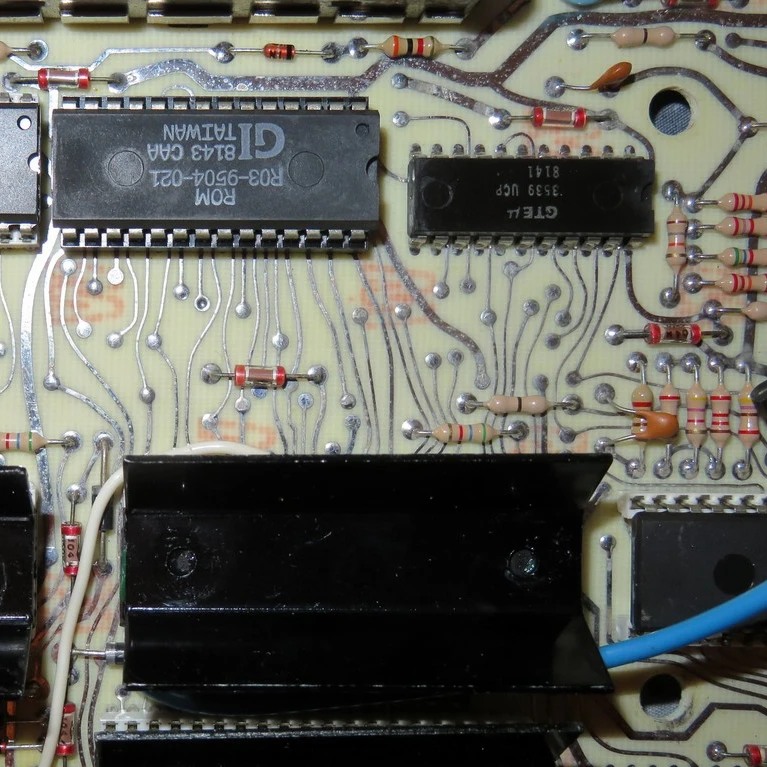

PS: I have compiled a list of pics of curved routing from various sources online to show what people have done.