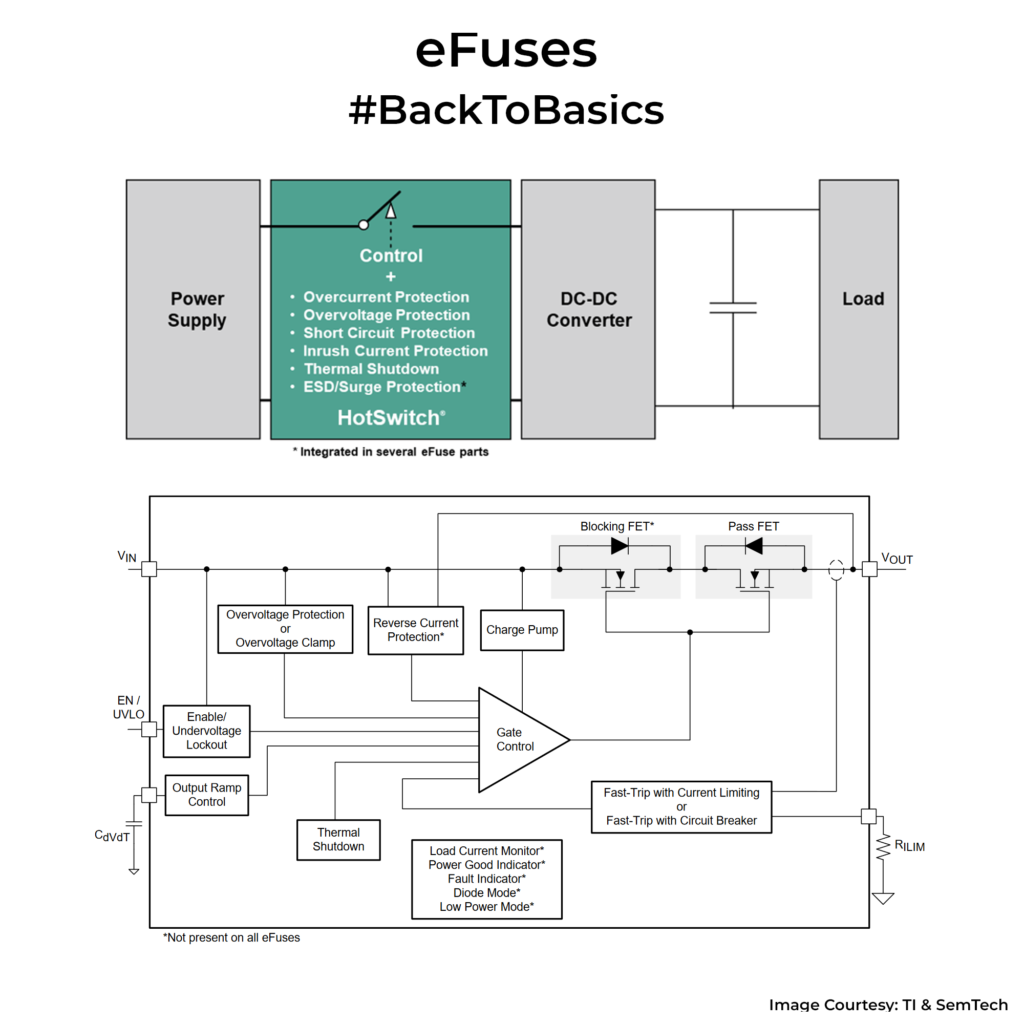

Most of you would be familiar with a power line fuse (If not, please refer to my older posts). Fuses are parts put in series at the input stage to protect the circuits downstream. Thermal fuses protect either by sacrificing themselves(one-time fuses) or by self-cutting-off to reduce overcurrent. There is another class of devices called eFuses whose sole job is to provide better protection to your circuits than discrete/thermal fuses.

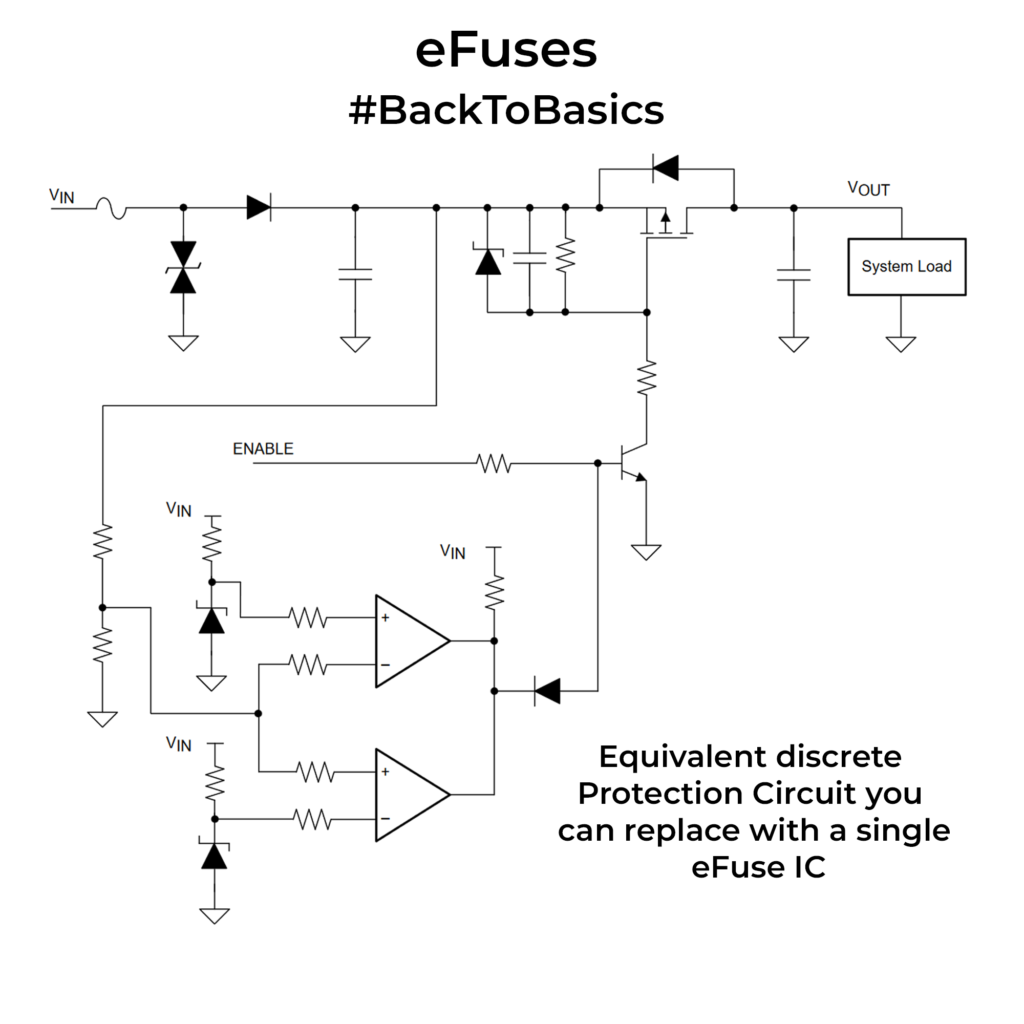

eFuse is an active IC solution with protection features against overcurrent, overvoltage, undervoltage, reverse polarity input, and inrush current. Think of it as an all-in-one solution for circuit protection. Let’s take an example of short circuit protection. Discrete PTC fuses work by changing their resistance when a trip current is hit, but the reaction time is pretty linear and takes time. Meaning that the chances of the circuit going up in smoke are high. Whereas eFuses are much faster to react in these scenarios cutting off power nearly instantaneously(Less than a 1ms!). You need a lot of components to provide the same protection for all the above to even get remotely close to the functionalities of eFuses ie) it takes up circuit space.

eFuses absolutely shine in cases where there are parts that will get plugged in “hot”(Think server parts, SSDs/HDDs, Motors that get pulled in and out while powered on). There will be a huge inrush current trying to charge the decoupling capacitors of the hotplugged device, which can cause voltage droop in the rest of the circuit. This is solved in eFuses by doing a controlled ramp-up of the voltage and current for the circuits it’s protecting. All in all, eFuses are the one-stop solution if you need all these protections. Yes, they are slightly more expensive but worth it when you are protecting high-value components in your circuit.

Have you used them before? Would love to hear about your experience working with them.