When it comes to LEDs, it’s not just about the light they emit; it’s about how they handle the heat! LEDs are sensitive beings; they don’t bode well under excessive heat. Heat adversely affects their efficiency, light output, and overall longevity. If you’ve ever seen a decline in LED brightness over time, heat is the problem. Excessive temperatures can lead to a phenomenon known as “thermal runaway,” where the LED’s performance spirals out of control, shortening its lifespan and compromising its luminosity.

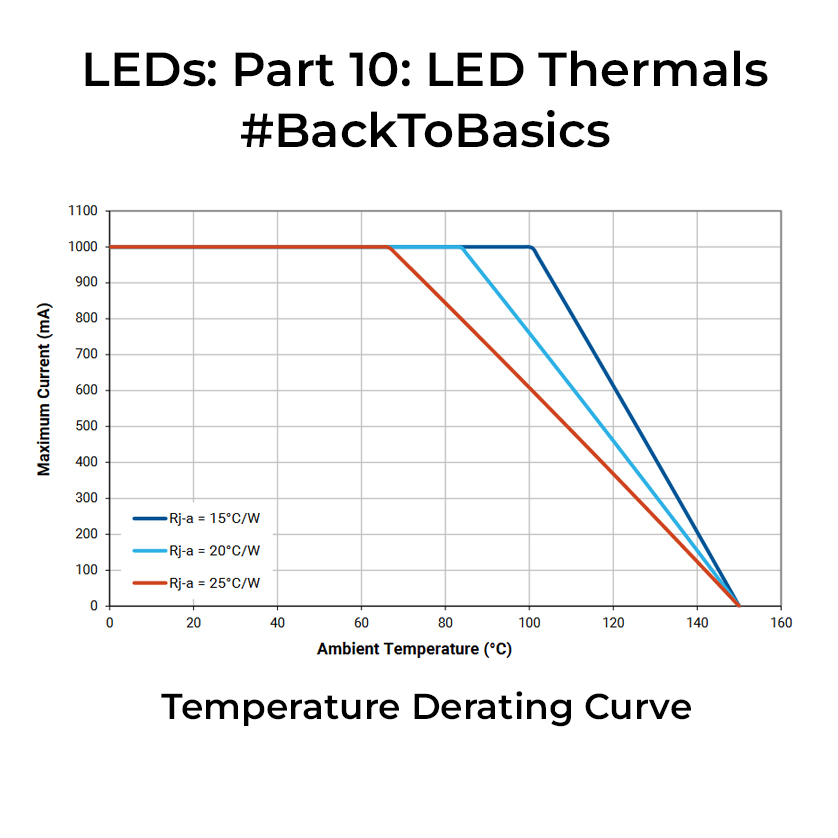

LEDs generate heat primarily through the forward voltage across the semiconductor junction. Higher the current, more the heat produced. Heat output can be assumed to be around 80% of the input power given to the LEDs(rough estimate). Do note that forward voltage decreases as the junction temperature of an LED increases. Temperature increase can cause colour shifts in emitted light too. There will be a graph in the LED datasheet called the temperature derating graph, which plots LED current vs LED temperature. It gives a safe operating region for an LED for a given temperature. Always keep within its limits.

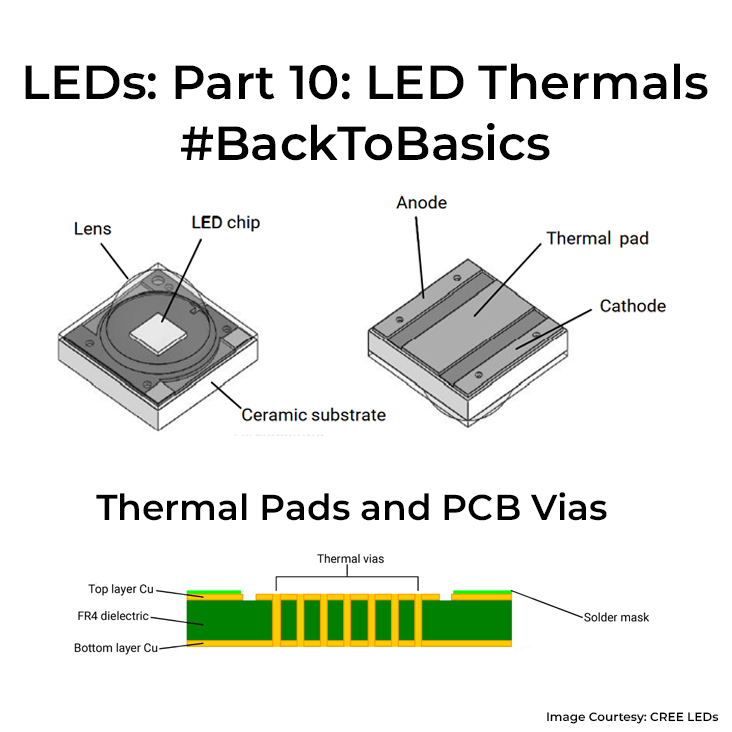

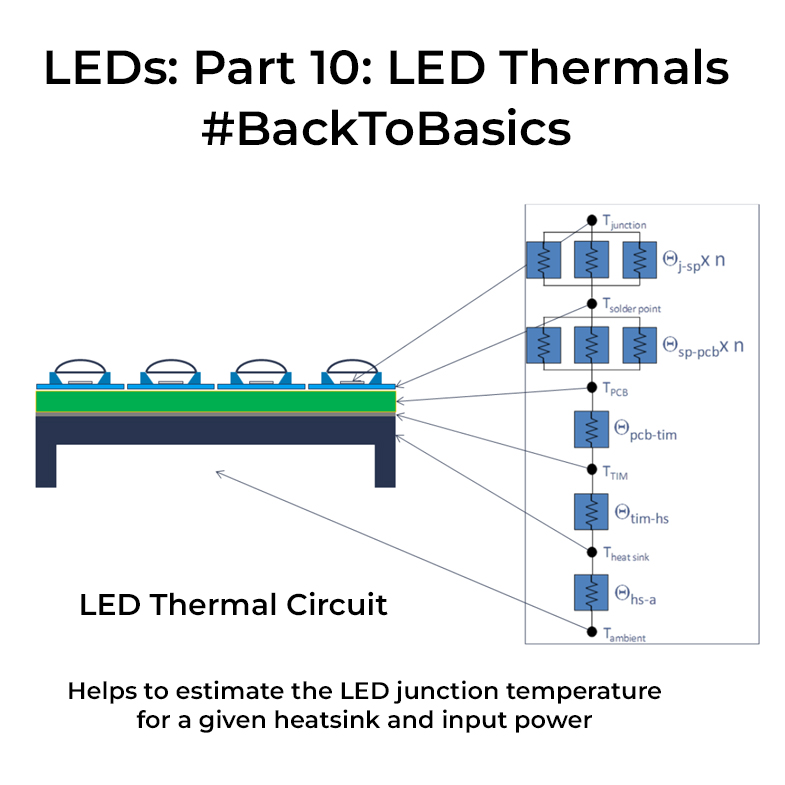

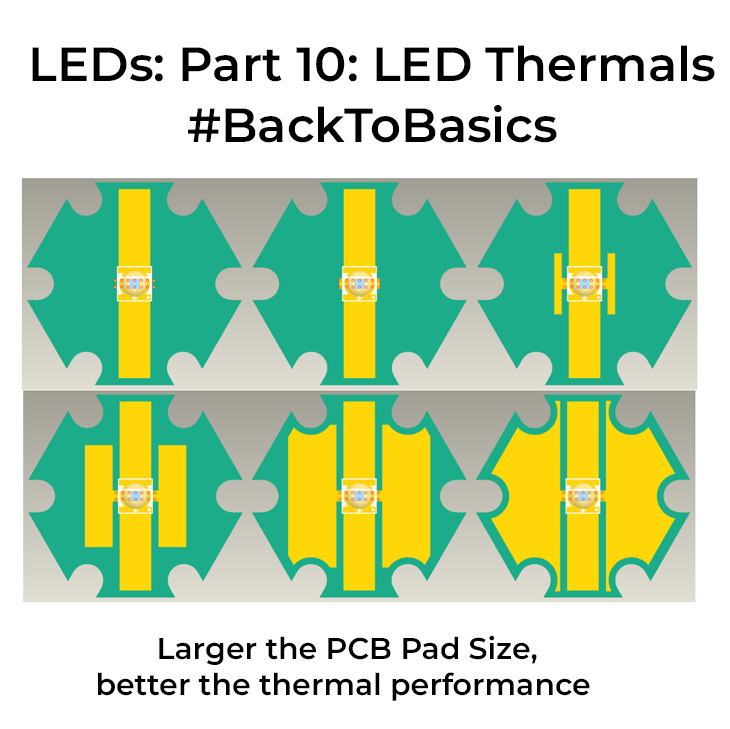

So how do you keep your high-power LEDs cool? Heatsinks are the most common solution. They come in all shapes and sizes. Thermal heatsink design is simple but too long to explain here. Dave from EEVblog has a few videos on how you can do that, with thermal resistances from the heatsink’s datasheet, to keep your LED junction temperature in check. A commonly overlooked aspect by newbies is LED thermal vias and connecting them to the large ground planes. Surprisingly, you can utilize PCBs, both Aluminium and FR4, as effective heatsinks, provided they are sufficiently large. For critical applications, consider integrating a PTC thermistor. Typically positioned near the LED at a test point, it actively measures real-time heat, enabling the regulation of driver current via feedback. This, in turn, acts as a safeguard against thermal runaway, ensuring the stability and long life of your LED system.